Modified IKEA Sektion Cabinet Installation For Office & Studio Use (Installation Without Sektion Legs Or Suspension Rail)

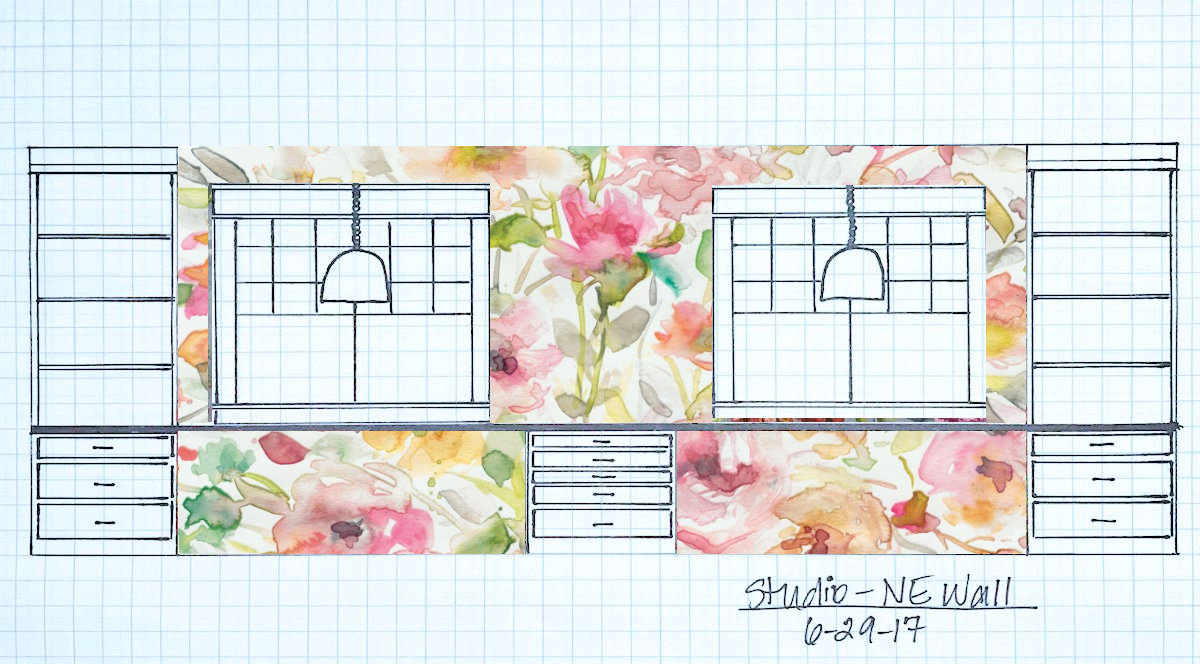

I had a choice between installing the new studio bathroom wallpaper or installing the studio cabinets this weekend, and I decided to install so the studio cabinets. So if you showed up here today hoping to see the wallpaper installed, I’m so sorry! You’ll have to wait a bit longer. But seeing the IKEA Sektion cabinets finally installed on the long wall of the studio is pretty exciting!

This wasn’t exactly a straightforward installation of IKEA Sektion cabinets. The Sektion cabinets are made to be used in a kitchen, and standard kitchen cabinet height is 36 inches. So the cabinet boxes are 30 inches high, and once you add the legs that IKEA sells for them, and then add a standard thickness countertop, that puts the countertop right at 36 inches high.

Well, I didn’t have 36 inches of height to work with since I’m using these in my studio on a wall with two windows which were installed at the perfect height to allow for a standard desk-height countertop, which is 30 inches high.

Since I’m not really using this as a desktop, I don’t mind the finished countertop being a little higher than 30 inches, so it just needed to be somewhere between 30 inches high and around 34 inches high.

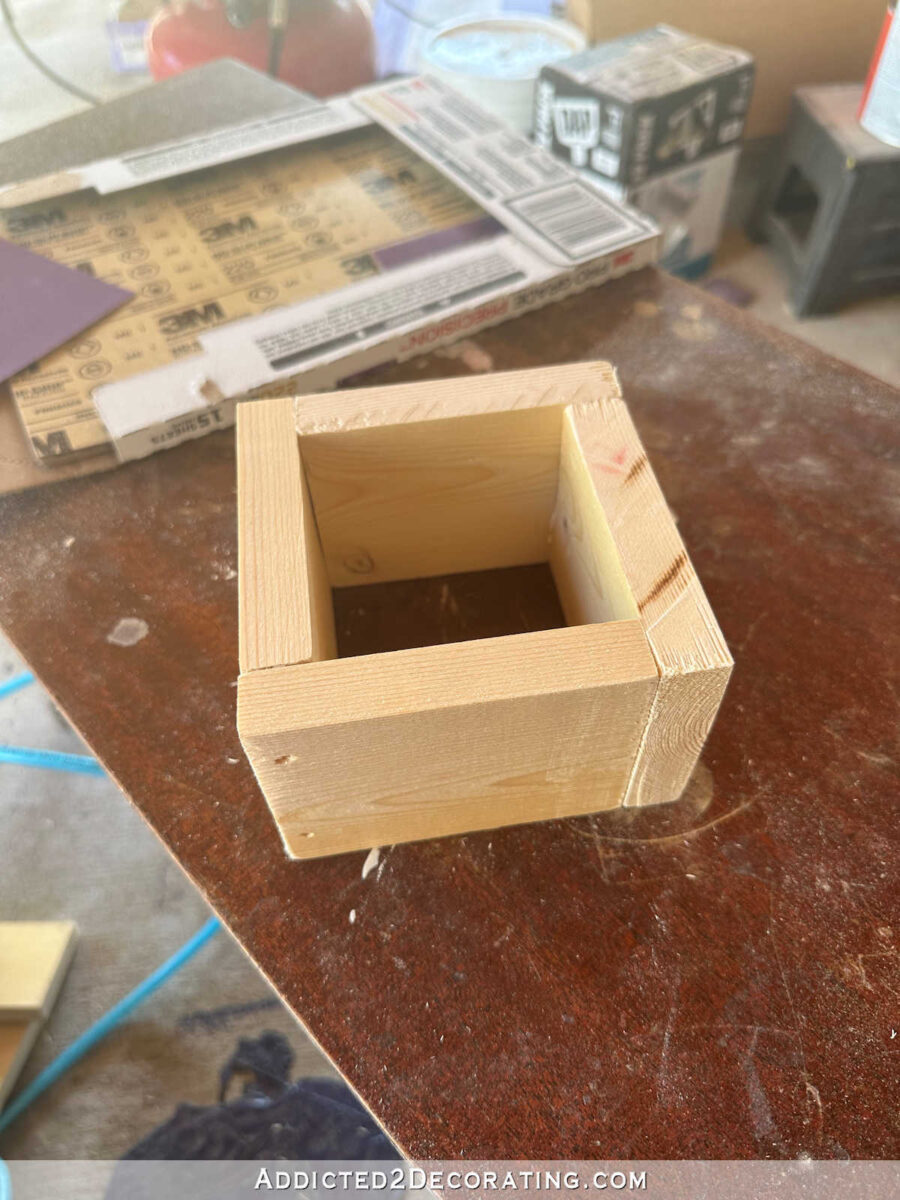

That means that the IKEA legs wouldn’t work for my purposes. The minimum height for the IKEA legs is 3.5 inches, and the highest I could use is 3 inches. So I ended up making my own very rough feet out of 1×4 lumber that I ripped down to 3 inches, and then cut into 4-inch-long pieces. I made each foot out of four pieces, glued and nailed together using 16-gauge 1.5-inch nails in my nail gun.

I wasn’t concerned with them being pretty since they won’t show on the finished cabinets once all of the trim is installed. I just needed all of the feet to be a consistent 3 inches high.

Once I had all of the feet made, I placed my cabinet boxes on the floor front down, and then attached the feet using hot glue. I know a lot of people don’t trust hot glue because they’ve only ever used those dinky little hot glue guns that you buy at the craft store. But when I talk about hot glue, I’m talking about an actual hot glue gun that you buy in the tool department of Home Depot or Lowe’s that puts out a very thick bead of glue.

When attaching the front feet, I made sure the front of each foot was flush with the front of the cabinet (which was simple to do with the cabinet face down on the floor) since I don’t plan on having a toe kick on these cabinets. If I had wanted a toe kick, I would have moved those front feet back four inches.

Once I had those attached, I placed the cabinet right side up, and it looked like this…

When I ordered my cabinets, I wasn’t really sure exactly how I was going to install them (I was still deciding on how I wanted my finished cabinets to look), so I didn’t order the suspension rails that are generally used to install the Sektion cabinets. Ordering them separately at a later date would have cost $120 just for shipping. So I decided to skip the suspension rail and just attach the cabinets to the wall without the suspension rails.

The problem is that the studs in the wall weren’t directly lined up with the brackets that are used to screw the cabinets to the wall. (These brackets come with the cabinets.) So before trying to attach the cabinets to the wall, I screwed some 1″x4″ boards horizontally to the wall, screwed into the studs. That way I could install the cabinets anywhere along the wall and have them screwed securely into these boards.

I also ripped a small strip of lumber to place close to the bottom of the wall so that the bottom of the cabinet would be plumb with the top.

Before screwing the cabinets to the wall, I had to make one small modification. These brackets that come with the Sektion cabinets are adjustable. If you’re going to use them with the IKEA suspension rails, you install them using the screw holes closer to the front of the cabinet (pictured below) so that the bracket protrudes out the back of the cabinet slightly. Then the bracket attaches to the suspension rail in a similar way to a French cleat.

But if you’re not using the suspension rails, and you’re just screwing the cabinet directly to the wall, you use the back holes to attach the brackets. This brings the bracket forward and makes the back of the bracket flush with the back of the cabinet.

And then these little black filler pieces insert into the bracket on the backside.

Below is a side view showing what the bracket looks like when it’s installed to be used with the suspension rail. The metal bracket just hooks over the top of the suspension rail, which is why it needs to be set back further and not be flush with the back of the cabinet.

But here’s the side view when the bracket is installed for the cabinet to be screwed directly to the wall. Once the black plastic piece is inserted, it’s flush with the back of the cabinet so that the cabinet will sit right against the wall (or in my case, right against the wood strips that I attached to the wall).

Once I had all of the brackets adjusted, I placed the first cabinet in its place, and then put screws through the middle of these big holes in the brackets and into the wood.

And then I placed these little metal pieces (which come with the cabinets) over the screws.

I didn’t tighten the screws just yet. I waited until I had all of the cabinets in place before going back and tightening these screws.

And here’s a side view of the first cabinet installed…

With that first center cabinet installed, then I worked out from there. I moved the next cabinet into place, clamped it to the first cabinet, predrilled four holes, and screwed it to the first cabinet using the screws provided with the Sektion cabinets. And then I screwed it to the wall (but didn’t tighten the screws completely), and moved on to the next cabinet.

The process wasn’t difficult at all. With an extra set of hands, it would have been a very quick process. Working by myself definitely slowed things down, but it was very manageable.

Once I got all of the cabinets screwed to each other and screwed to the wall, I started in the middle and tightened all of the wall screws.

Once those screws were secure, I covered the brackets with the plastic covers that come with the Sektion cabinets.

The last thing I needed to do to prepare for trim installation was to fill in the spaces at each end. I used 2″x2″ lumber cut to the proper height, and using my trusty hot glue gun once again, I attached those to the sides of the end cabinets, making sure that the front of the board was flush with the front of the cabinet frame.

That way, when I attach the 5/8-inch-thick trim board to the front of this spacer board, the trim board will be flush with the fronts of the cabinet doors.

So this is as far as I got this weekend. Next up, I’ll be trimming out these lower cabinets, and then installing the countertop.

My goal is to have the countertop finished and the two upper cabinets put together by Wednesday night so that some strong men in our Wednesday night group can lift those upper cabinets and put them into place for me. 😀

I’m so excited about the progress! I’ve been dreaming about this room, and specifically this wall, for so long, and I’m so anxious to see it finished!

Oh wow, that looks great. I bet you are getting excited to see this wall of cabinets in. Your storage is going to be incredible! Looking forward to the next section.

The studio is really coming together! I’m sure you must be so excited.

It is exquisite!

I like the way you used the 2 x 4 boards attached to the wall studs and then attaching the cabinets directly to those instead of using the suspension rail. I think this make the cabinets more secure and hold up longer. Especially like the strip of board you installed at the bottom wall to insure cabinets stay plumb.

Once again, all I can say is ‘great job’!

It looks bright and cheerful! Love it! I’m glad you did the cabinets before the bathroom. It made a huge impact.

Wow—great going! And, I sometimes use the fence finials for legs, the ones shaped like bun feet or acorns. I just pull the screw out and then work fine. They can be cut down too, quite easily. Looks great! Elizabeth Denning

Wow. Just wow!

I’m curious why you decided against having a toe kick.

If this were going to be a work table that I’d be standing in front for long periods of time, I’d have a toe kick. But as the plan for this wall has evolved, it’s now going to be more of a storage surface (for sewing machine and other items like that), so I’m eliminating the toe kick. I prefer the look of built-ins without toe kicks, so if I don’t need a toe kick for practical purposes, I’ll always opt to eliminate it.

I love these posts that detail out what, how, and why you do things.

That new wallpaper is fantastic. I hate ditzy patterns, and enlarging the flowers makes a huge, colorful statement. Gorgeous!

I realize you’ve installed lots of cabinets. But, since you’ll be using the top of the surface of these cabinets to work on, the absence of the toe kick will be SO uncomfortable every time you walk up to them. Please reconsider.

This isn’t a work surface. I have two huge work tables for that.

You’re a genius! How on earth do you know how to do all this stuff?

I just love the way you problem solve. Thanks for sharing your thought process as you put this all together – I always learn something (like go buy a real glue gun). So excited for you to have your very own Office/Studio!

I would love a nice big workroom with all this storage! You lucky girl!

I’ve see where a guy had to do uppers alone, and he fashioned a “prop” to hold the cabinet. It was just 3 -2×4’s, two were legs cut to the height of the underside of the cabinet, and the third was cut to sit inside the bottom underside of the cabinet. He temp. screwed this into the bottom (not all the way, just enough to hold) then set it upon the wall and screwed the cabinet into the wall and undid the screws underneath. It worked well for him, but two strong guys would be easier!

Forgot to add that this won’t work for you with the base units installed, but maybe keep in mind for future use!

This is going to look amazing! I’m so excited for you and can’t wait to see it all come together!

Did you have to worry about keeping the two wood pieces you attached to the wall being plumbed to each other? If so, what tricks do you use to keep everything plumb and aligned? My DIY projects always get tripped up on things like this.

It’s so exciting to see so much progress!!!

Yes, we’re installing an IKEA kitchen right now and I was reading I was thinking how this method would not work for us without some extra steps, as our floors aren’t level and our walls aren’t flat or plumb!

It is going to look so good. You have every right to be happy. How exciting!! You are almost there in getting your studio finished. You are so talented and can figure things out. I would not know where to begin with what is going on. I’d know how I want it to look, but not how to get there.

Thanks for taking the time to type up this blog for all of us to enjoy. Keep up the good work.

You do great work. It is so inspiring to see how you have put together your projects!!

Nancy in N.C.

I am so glad I came across this article. You describe exactly my issue with installing the Sektion base cabinet for a counter that will not be at the 36 inch height that IKEA assumes. I was planning on using a leftover piece of suspension rail from an earlier installation in my basement, but your way of managing this by attaching a cleat to the wall to get the perfect height is much simpler. Your photos and explanations are clear and so easy to follow.