My Office Area Studio Cabinets — From Start To Finish

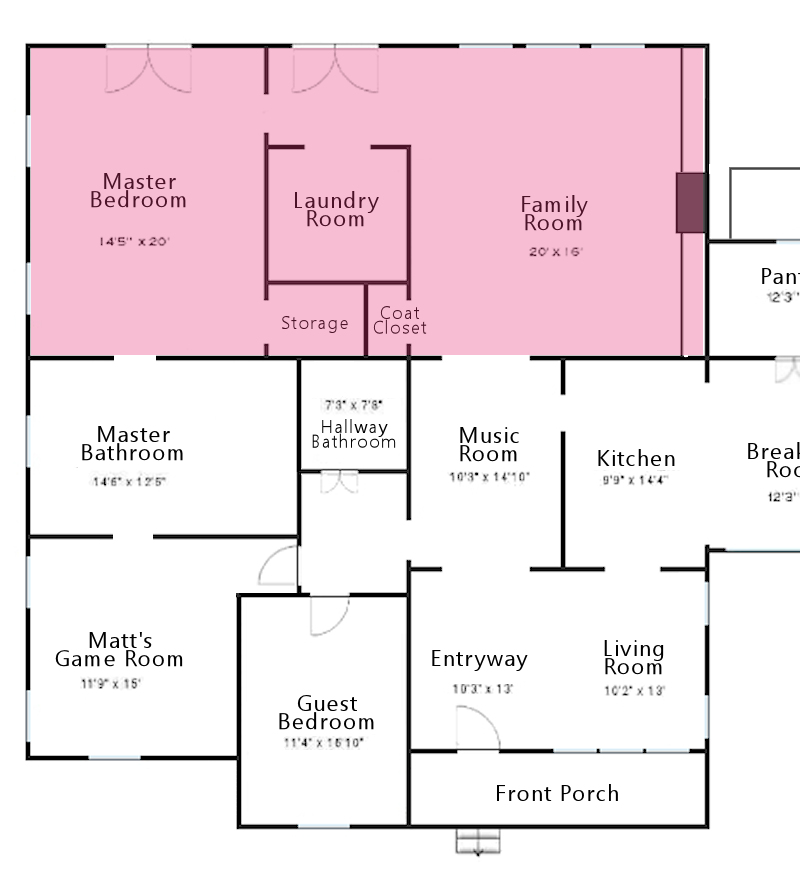

The cabinets in the office area of my studio took me so long to finish, and covered so many blog posts, that I thought it would be helpful to condense all of the info into one post with links to the specific posts that you will find helpful if you want to customize IKEA Sektion cabinets in a similar way. So let’s start at the very beginning.

Much of this process was exactly like the process I used to on the mural wall cabinets. I detailed that process from beginning to end here: Installing IKEA Cabinets In An Office/Studio — The Process From Start To Finish

Those cabinets, which are also IKEA Sektion cabinets, turned out like this…

So while much of the process was the same for the office area cabinets, there were also a lot of additional steps required to get the office area cabinets to look like this…

So I’ll start at the beginning and go through the process for these cabinets.

Prepping the cabinet boxes

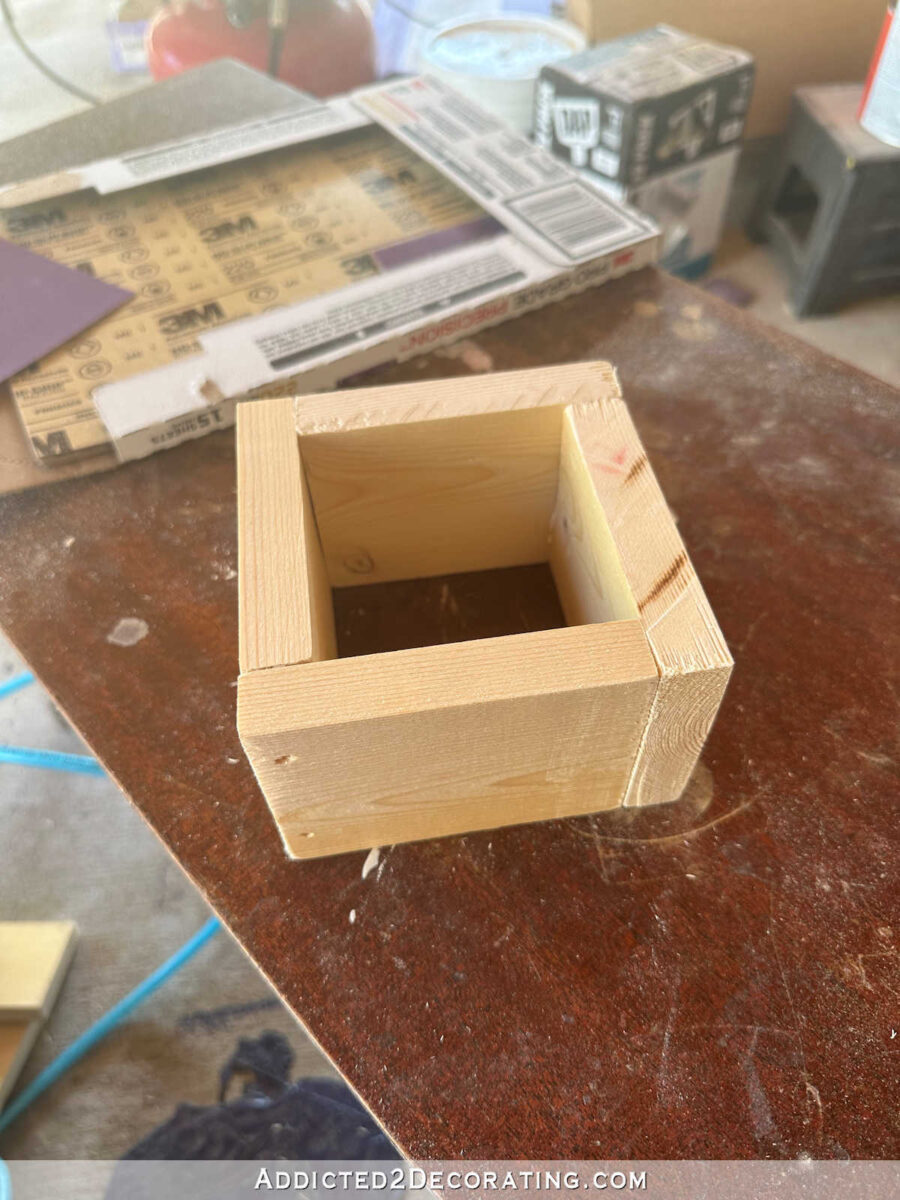

After putting the cabinet boxes together according to the instructions provided with the IKEA Sektion cabinets, I made and attached my own feet rather than using the feet that you can purchase separately from IKEA for the Sektion cabinets. The reason I did this is because I needed a very specific height that was shorter than the shortest possible height that the IKEA adjustable legs provide. So I just used 1″ x 4″ lumber, cut down to the right width on my table saw, and then cut, glued and nailed four pieces together for each foot that I needed. They didn’t need to be pretty since they wouldn’t show on the finished cabinets.

And then I attached those to the bottoms of the lower cabinets using a hot glue gun.

Installing the IKEA Sektion cabinets

I also didn’t use the rails that IKEA sells for securing the cabinets to the wall. Instead, I used 1″ x 4″ lumber, attached to the wall by screwing it into the studs, and then I used the hardware provided (screws and brackets) with the cabinets to screw the cabinets to the 1″ x 4″ board, and also to screw the cabinets to each other.

I went into much more detail about this process here: Modified IKEA Sektion Cabinet Installation For Office & Studio Use (Installation Without Sektion Legs Or Suspension Rail)

And here’s where this cabinet installation became very different from the mural wall cabinet installation. Once the lower cabinets were secured to the wall and to each other, I added the side upper cabinet boxes, screwing the boxes together as I went along.

With all of the boxes assembled and secured to the wall and each other, this is what it looked like…

Customizing and painting IKEA Veddinge doors and drawer fronts

I used Veddinge doors and drawer fronts because they’re flat and made of MDF, so I thought they would be the easiest to customize. I sanded each one on the front and back…

And then added trim to customize the look…

After the trim was attached and caulked, I used BIN shellac-based primer to prime the doors and drawer fronts using my sprayer.

And then I gave them two coats of paint, followed by two coats of General Finishes High Performance Topcoat in a flat finish (affiliate link).

This is the sprayer that I use any time I want to spray cabinets or furniture (affiliate link). It’s identical to the Critter siphon gun that I used to suggest, which inexplicably skyrocketed in price about a year ago (but seems to have come back down to a reasonable price), except that this one has a plastic container instead of glass. I actually prefer the plastic because if I happen to drop it or it rolls off of my work table (which seems to happen at least once every time I use it), it won’t break. The glass container on the Critter breaks every single time.

I use the sprayer with my Porter Cable pancake air compressor (affiliate link). Several years ago, I shared a comparison between the two paint sprayers that I own, and why I always choose this particular paint sprayer for spraying cabinets and furniture.

See the paint sprayer comparison here: The Best Paint Sprayer For Kitchen Cabinets (Plus Tips On Getting A Beautiful Finish)

I sanded by hand with 220-grit sandpaper between each coat to ensure the best finish possible.

I went into more detail about how I trimmed and painted my Veddinge doors and drawer fronts here: Prepping My IKEA Veddinge Cabinet Doors & Drawer Fronts For Paint — Sanding, Adding Trim, Etc.

Building out the cabinets and wiring for sconces

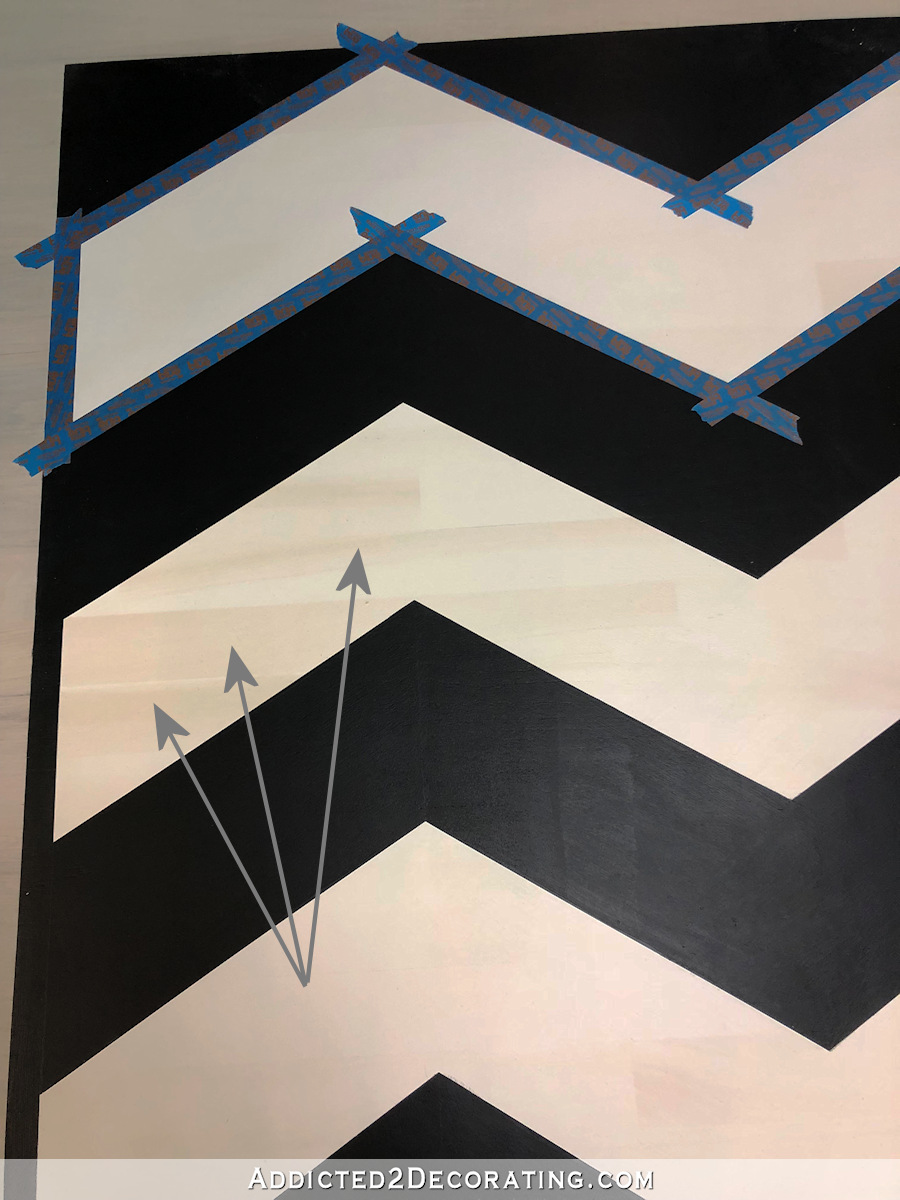

I did not want these cabinets to have the look of full overlay doors and drawer fronts when they were finished. I wanted them to have more of an inset look when they were finished. So that required quite a bit of work with the addition of lots of spacers, plywood side panels, and lots of planning to get them just right.

I detailed all of those steps in this post: Studio Office Cabinet Progress — Building Out The Cabinet Boxes & Running Electrical For The Sconces

The basic idea is that I needed to not only build out the sides of the cabinets, but also provide area for front trim to be attached to, as well as add space for electrical wires to travel through.

And I did that by adding two 2″ x 2″ pieces of lumber to each side of each cabinet…

And then attaching plywood to those 2″ x 2″ strips. (I used plywood instead of the IKEA side panels since I was going to be priming and painting.)

That allowed me to add trim to the front edges (turning the doors and drawer fronts from full overlay to inset), and it also allowed me to run wiring to add sconces.

But again, every step of that process is detailed in the post linked above.

Building the bridge

I decided to build a bridge connecting the two side cabinets mainly because without the bridge, the cabinets seemed to be a bit dwarfed by this very large and tall wall. You can see what I mean in this photo.

I felt like adding a bridge would make the cabinets look much more substantial on that big wall, as well as giving the cabinets a more custom look.

You can see the step-by-step process in detail for building the bridge here: Cubby Bridge Basic Build

Trimming out the cabinets

Once all of the basic build was finished, I was finally ready to trim out the cabinets. Adding the decorative trim is always fun because it really gives the cabinets a finished and customized look.

I went over this process in detail here: Trimming Out The Cabinets.

I also shared a “cheat” method for creating the look of substantial crown molding without the hassle of having to actually cut crown molding.

I shared the details of that process here: How To Make Faux Crown Molding That’s Very Easy To Cut And Install

Here’s what the faux crown molding looked like once it was installed.

And here’s how the cabinets looked once they were all trimmed out…

And after that, it was just a matter of priming, painting, and clear coating the cabinets before I could install the doors and drawer fronts.

Building the countertop

I made the countertop on this section of cabinets in the exact same way I made the long 20-foot countertop on the mural wall section of cabinets.

I shared the process of building a countertop out of laminate flooring here: Long DIY Countertop Made With Laminate Flooring (How To Make A 20-Foot-Long Countertop For Around $300)

The main difference between that long 20-foot countertop and this smaller one was that this smaller countertop required returns on the ends since the countertop sat between cabinets, with the the countertop projecting about an inch past the front of the cabinets, instead of sitting between two side walls.

I shared details specific to this smaller countertop sitting between cabinets here: The Second Studio Countertop Is Finished!

The finishing details

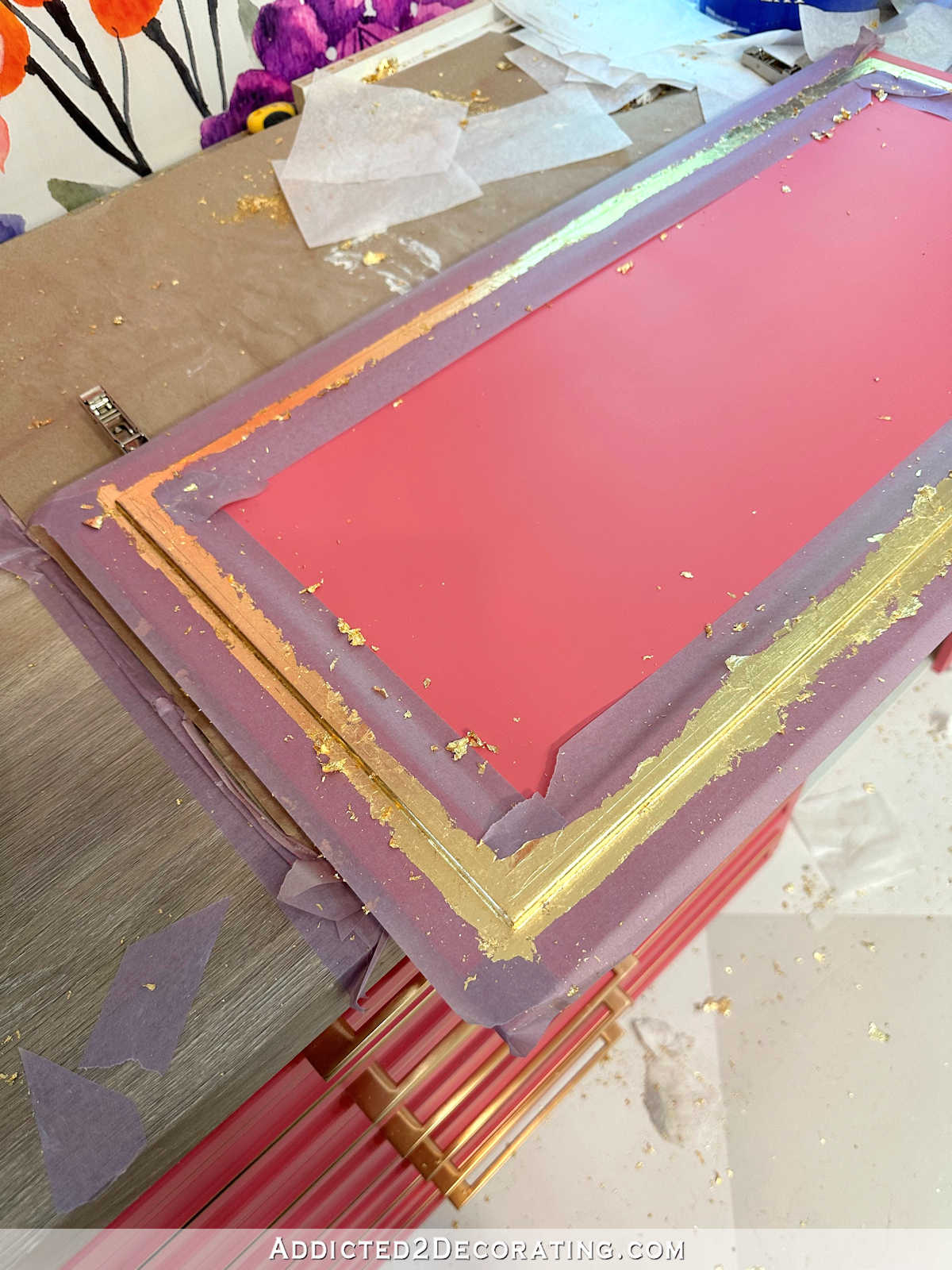

And with a few more details, like installing the window trim, installing the sconces, and gold leafing the backs of the cubbies, and adding the drawer and door pulls, the cabinets were finished!

So Beautiful, and SUCH an amount of work you did! In the end, an incredible space, and getting better and better everyday! You should be so proud, and happy about the progress and the finished product. You do such an amazing job finishing…things are perfect, and the finishes pristine. I don’t see that ever with workers…slap on the paint and move on! They have no clue. And me…I can’t be that patient either. 😏

In reference to an earlier discussion I had the idea of you putting the PAINT SAMPLE CABINET on the big wall. Centered with calendar on each side.

Love your room!

Do you use the paint sprayer to apply the top coat too?

I did! Primer, paint, and topcoat, all sprayed.

Kristi,

You are an awesome teacher and explainer! Thank you for sharing your process and your results with us!

Cathy

I just love your statement,,,,”And after that, it was just a matter of priming, painting, and clear coating the cabinets before I could install the doors and drawer fronts.” ?????? Just????? JUST?????? Wow! You have accomplished an insane amount of work using all your creative skills and the results are truly amazing. I absolutely love the end results. Congratulations on work beautifully done!!!!!