DIY Wingback Dining Chair – How To Build The Chair Frame

I’ve been both excited and nervous about tackling this DIY chair project — building my own wingback dining chairs from scratch. I wanted to challenge myself with a project I’ve never done before, but I also knew it could wind up being an epic failure.

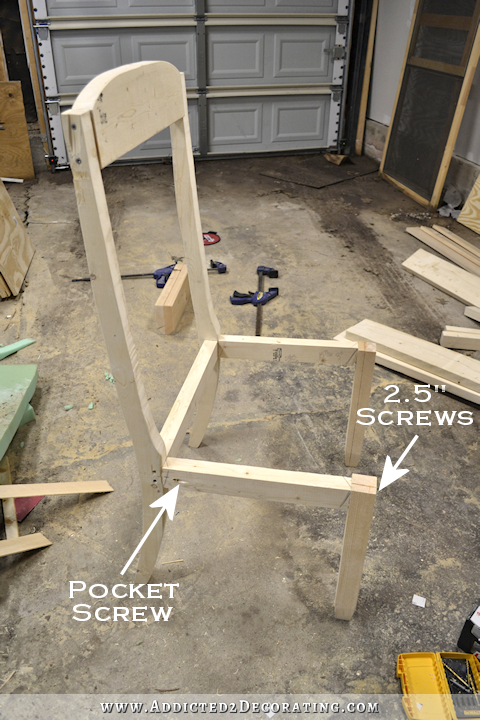

Thankfully, I think it’s actually going to work out! I got the basic frame built for one of the chairs yesterday. Here’s how it looks…

Of course, almost the entire thing will be covered with foam, batting, and fabric by the time it’s finished. Only part of the legs will show. I also still need to add a few support pieces that the foam, batting, and fabric can wrap around and be stapled to. I’ll show that in the next post. But for now, I’m just relieved to have the basic frame done, and to see that it actually looks like a chair! 😀

How To Make A DIY Chair Frame

Here’s how I did it…

The back legs are the most important thing to get right on a DIY chair because of the angles. In order to get it right, I used one of my dining chairs as a template. I placed it onto a 2″ x 6″ piece of lumber, and traced around the entire side piece, from the bottom of the leg to the top of the side back.

Two areas I really concentrated on lining up correctly were (1) the very bottom (i.e., “foot”) on the leg. I wanted it perfectly straight so that it would sit right, and (2) the area where the supports for the seat are attached. Those areas also needed to be perfectly straight, so I lined them up with the very edge of the 2″ x 6″ board. I also marked where the top of the seat support attached to the leg. It was somewhere around 16.5 inches from the bottom.

And then I used my jigsaw to cut out the back legs.

I then used that piece as a template to trace three more pieces (since I’m making two chairs).

For the front legs, I wanted them to be 2.25″ square, so I cut two lengths of 2″ x 6″ lumber for each DIY chair (FYI, 2″ lumber is actually only 1.5″ thick), glued the two pieces together, and clamped them until they dried. What you see here is enough to make four legs — two for each chair. In other words, they’re just glued together in pairs. There’s no glue between the two center pieces.

While those dried, I finished assembling the back of the DIY chair. I made the top piece by cutting a piece of 2″ x 6″ lumber to 19.5″ wide. After creating a pattern with paper for the arched top, I traced the arch onto the board and cut it out with my jigsaw. Then I ripped several pieces of 2″ x 6″ lumber down to 2.25″ wide to use for the seat supports. I cut one of them to 19.5″ long to use for the bottom support.

Then I assembled those pieces using lots of wood glue and 2.5″ wood screws. I made sure to line up the top of the back seat support with the lines that I had marked from the template (i.e., when I traced the leg from the chair) so that I would have the proper seat height. You can see my faint pencil marks lined up with the top of the back seat support in this picture…

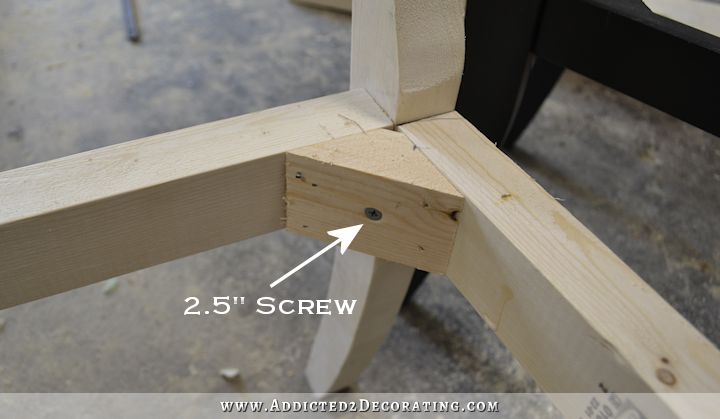

Here’s a side view. You can see that on each piece, I just drilled right through the outside of the side support and into the ends of the cross pieces. I pre-drilled all of these holes and used 2.5″ wood screws to hold the pieces together.

After allowing the clamped wood for the front legs to dry several hours, I unclamped them and used my table saw to rip the pieces to 2.25″ square. The front legs were 16.75″ high.

I used my miter saw to cut a very subtle taper on the bottom of the front legs so that they wouldn’t just be completely square from the top to the floor, but I failed to get a picture of it. You can see the taper on the bottom in the pictures below, though.

Then I cut the side seat pieces using more of the 2″ x 6″ lumber that I had ripped down to 2.25″ wide. I cut those pieces to 16″ long, but in hindsight, I wish I had made them just a bit longer. 16.5 or 17 inches would have been preferable. I attached those side seat supports to the back side supports using pocket screws and wood glue, and then attached the front legs by screwing 2.5″ wood screws straight through the front of the legs and into the ends of the side seat support pieces. Again, I pre-drilled the holes. I pre-drill ALL of my holes when building stuff like this. If you don’t pre-drill, you risk splitting the wood.

Just a note about the side seat supports: I used the other dining chair to get all of the measurements, like the seat height, front leg length, etc. On the area where the side seat supports attach to the back side supports, the top of the side seat support is about 16.5″ from the bottom. However, the front legs are 16.75″ high. That means that the seat has a very slight angle to it, so the ends of the side supports needed to be cut at slight angles. I avoid geometry at all costs, so I just tested out some different angles to see what would work. I found that cutting the ends of the side seat supports at 2.5 degrees worked perfectly to give that ever-so-slight angle to the seat so that it was just a tad bit higher in front and angled down towards the back.

And then I finished up the main frame of the seat support by adding the front piece, cut to 19.5″ long, and secured with wood glue and 2.5″ screws through the sides of the front legs and into the ends of the front support piece. I just used one screw on each side to attach this piece.

To add more support for the seat frame, I cut four corner pieces with 45-degree angles and attached it with wood glue and 1.5″ 16-gauge nails in my nail gun. Then I added one screw going through the center of the corner support and into the leg.

Here’s a view of one of the back corner pieces, secured with wood glue, four nails going into the side support pieces, and one screw going diagonally into the leg.

I did end up using one screw between the nails on each side of each corner support, but I failed to get a picture of that. So in the end, each corner support was attached with wood glue, four nails, and three screws.

Next, I cut a piece of 3/4″ plywood for the seat using my jigsaw and attached it with wood glue and 16-gauge nails.

Just a note about the seat. I used a plywood base because these are dining chairs. I prefer a firm seat on dining chairs because if the seats have too much give to them, you can end up sitting too low at the dining table. It’s probably less of a problem for most people than it is for me since I’m just 5 feet tall. 🙂 But if I were making occasional chairs rather than dining chairs, I’d forgo the plywood and use jute upholstery webbing for the seat. And if I were making living room chairs, I’d probably take the time to learn how to use actual springs. I’ve watched videos of springs being added to chair frames, and it doesn’t look difficult. Springs can be purchased at upholstery supply shops.

But since mine are dining chairs, and I like my chairs very firm, I used plywood. 🙂

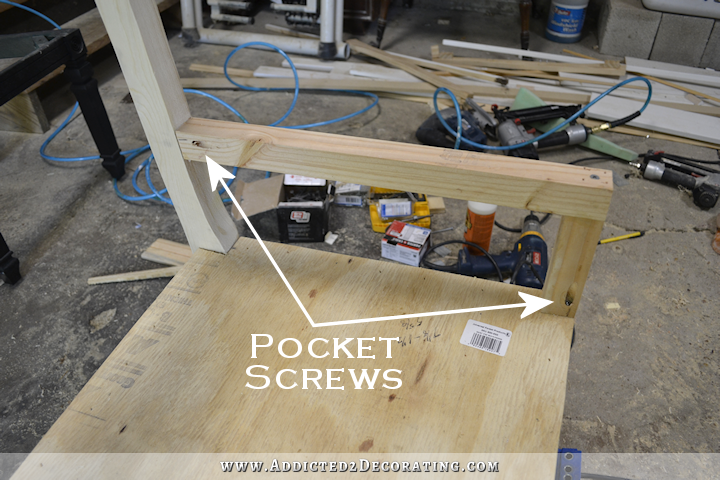

Next, I created the arm framing by ripping 1.5″ square pieces from the 2″ x 6″ lumber. The front short piece is 5 5/8″ high. I don’t recall the length of the long piece, but I cut it longer than it needed to be, and then held it in place to mark where it needed to be cut. It had to be cut at a slight angle to match the slight angle on the back support piece. After gluing/nailing/screwing those pieces together at a 90-degree angle, I attached them to the DIY chair frame using pocket screws. I used two on the outside…

…and two on the inside…

The main thing I had to keep in mind with the arms is that I had to keep the height low enough so that the chair would slide up to the dining table. That meant that the arms had to clear the apron on the dining table.

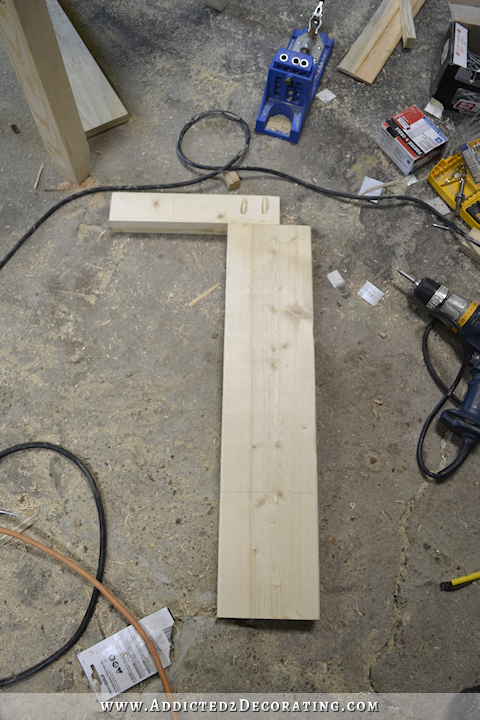

Next, I prepared the framing for the wings. I used more of the 2.25″-wide lumber that I had ripped for the top piece and then used a full 2″ x 6″ piece for the side. I attached those together with wood glue and pocket screws.

Then I held that piece in place on the frame and marked where each piece needed to be cut. Each one required a slight angle (which you can see in the photo below) to fit against the back supports and the arms.

Then I drilled more pocket screw holes to use to attach the wing to the DIY chair frame, and then I drew a curved wing design. I just freehanded the design until I had one that I liked. And the reason I offset the wood pieces is that I wanted the curve at the bottom (where it would attach to the arm) to extend past the top curve of the wing.

I cut out that design with my jigsaw, and before attaching it, used this piece as a template to trace the design onto the other three pieces. (I need four since I’m making two chairs.) Then I attached the wing frame to the chair frame using wood glue and pocket screws. And just like on the arm, I used pocket screws on the outside AND on the inside of the wing to make it very secure.

And after repeating that whole arm and wing process on the other side, I had the basic frame for a wingback dining chair!

Like I said, it will need a few more support pieces. When making a chair frame that will be upholstered, you have to keep in mind how the foam/batting/fabric will wrap around the frame, and where it will be stapled. Right now, I have nothing that the foam/batting/fabric can be stapled to where the chair back meets the chair seat, and I also don’t have anything to wrap the inside arm foam/batting/fabric around and staple to where the bottom inside of the arm meets the chair seat. And if that’s clear as mud, it should be much clearer when I actually get started on the upholstery. 🙂

But for now, here’s the 360-degree view of the basic DIY chair frame.

Having that other dining chair right there to use as a template throughout this building process really made the whole thing much easier. If you decide to take on a DIY dining chair building project and don’t have a dining chair to use as a template (especially for those back support pieces), I highly suggest taking a trip to Goodwill or Salvation Army and picking up a cheap chair that you can use as a template. If you don’t get those back supports right, the whole chair will look awkward and feel very uncomfortable.

UPDATE:

To see how I upholstered this chair, you can see Part 1 here.

Um..wow! I’m almost speechless… All I can say is that you are freaking genius! My father (carpenter) would love you for a daughter….lol..

Now that’s it !!!! And a hundred more exclamation points. You are not “fer reel.” What next , tearing an engine out of a jet?

I want to be you when I grow up.

My hero.

You are amazing 🙂

Fearless.

Yes, perfect word!!! FEARLESS!

Fantastic!!

You take my breath away…………….. No one woman (or any other sex or species) should be this damned talented…………..

What’s for tomorrow? Redesigning and making over the Eiffel Tower?!

Just what I was thinking! Beyond amazing. I am speechless.

Wow. Just wow.

Do you ever get tired of hearing how amazing you are? I’m showing this post to a carpenter friend who rebuilt our deck. And I thought HE was good when he curved the legs of the benches so they would fit in the space better.

This is soooooo splendid! When you tear the engine out of the jet, I want to be there. I think we should have a party celebrating your splendiforousness.

If you DID tear out a jet engine, I’m betting you’d be making something with it for your home. My husband used to make furniture, and he amazed me sometimes. But you top it all for figuring stuff out on your own. Can’t wait to see this finished. Absolutely. Incredible.

She wouldn’t be the first! http://gizmodo.com/sitting-in-a-737-jet-engine-chair-turns-anyone-into-a-s-1772239857

Haha! I’ve seen that chair and think it’s pretty cool. Could you try it sometime, Kristi?

Great idea using the other chairs as your pattern! I would have never thought about building my own chair- great job!!

To say that this is impressive is an understatement, Kristi. You’ve got mean math and mechanical skills, on top of design abilities. Cheers, Ardith

I am simply at awe of all the projects you do. Well done my friend, very well done!

Incredible! You really should teach! I bet there are tons of people who would love to do what you do – me included!

Is there anything you can’t do? Just the thought of making my own chair would never occur to me. You’re amazing.

Yes, speechless. Does your mind ever NOT see design? Do you sleep, ever? Wow. Just wow. And that jet engine? You’ll make it into a coffee table base we will all want. Thanks for sharing your inspiration for seeing things that aren’t there!

Oh, it’s Thursday. I think I’ll build a wing back chair. You are fearless. Can’t wait to see the finished chairs.

Yes, absolutely yes in agreement with each and every comment on here. Wow. Just WOW.

WOW….your fearlessness inspires me to take small steps toward my construction goals…This senior citizen is in awe of your talent…Soar on.

Yes, you are amazing, and your effort and patience are admirable. Wow !

I’m with everyone else. WOW! I don’t seem to have all the skills you have (funny how that works, huh?) but I can tell you that finding this blog has helped me overcome the paralysis that sometimes holds me back when I can’t buy what I want and I get too intimidated to try it myself. So, know you are a motivator and inspiration to lots of folks who might otherwise just say “I wish….” Thanks for putting yourself out there and letting us glean from you!

I can’t belive you, petite woman did it yourself! IT IS JUST NOT POSSIBLE! But you did it!

MY CONGRATULATIONS!

OMG! (I’ve started so many comments with WOW, that I had to come up with something different, LOL) You are truly a Renaissance woman! Can’t wait to see the finished product.

OMG, this amazing! Hands down, completely impressed. I cannot wait to see it when you’re all done! And am saving this as a tutorial, lol…just in case I get brave 🙂

Your talent at making things is freaking me out. You are truly a woman of many talents.

As usual, Great work! bold project that I love. I like you using the screws while figuring it out, (easier to fix/try again while experimenting), but how are you going to avoid hitting them when upholstering?! Could you just sink them in and plug/putty over? I could just be overthinking it too…

I think there’s still plenty of wood to staple into. I don’t think the screws will cause a problem.

Kristi, you are extremely crazy in a good way. Chairs from scratch! Wow. I can’t wait to see how this turns out. I have always thought it would be fun to be a skilled furniture maker and work for some really classy furniture company like Hardin or Ethan Allen or something like that.

Really? Wow! Did you not see that Kristi just BUILT A CHAIR! The rug that you mentioned is not what this blog post is about. KRISTI BUILT A CHAIR!!!

Um, yes I did. As I said, on the blog BETWEEN NAPS ON THE FRONT PORCH, which is completely different from Kristi’s, but sometimes just as interesting, she had this awful thing happen to her hardwood floors because of a rubber backed sisal rug. I saw the rug and immediately wanted to warn Kristi. At least 20 other people posted having the same problem and finding it difficult to find something that could get the rubber off, without damaging the floors. So please, you fool, give me s— for wanting to save Kristi from having to redo her floors. An ounce of prevention is worth a pound of cure. I guess your mother didn’t teach you that.

I knew I shouldn’t have engaged you. If you will notice on my post I didn’t take any personal shots at you. I tried to keep it positive. That’s what adults that have mothers that teach them manners do.

You have problems my dear!

Hi ,very interesting ,thank you

Okay, lady, you are amazing! Wow! Very inspirational, I tell ya!

Amazing Kristi does it again! I’m 62 yrs. old, and feeling every bit of it right at this moment. The thought of all the bending, knees on the floor, lifting and twisting to accomplish this makes me so jealous. My years of retail on concrete floors and outdoors at a garden center lifting 40 lb. bags of wet topsoil, etc. has done some damage that now limits me. So annoying to know I can do these things in my head, but not in reality!

You go girl, for as long as it feels good, but be sure to protect your joints and bones as well as your other working parts! Wish I knew then what I do now! Bravo on all you do!

I’m in total awe……..wow, Kristi, you are simply amazing. Nothing stops you. You are incredibly talented to think, design and make your own wingback chairs. The chair already looks amazing and I thank you for the detailed process. I’ve wanted 2 wingback chairs for our dining table and now with your pics and instructions…..I just think I could also do this. You give me such inspiration to DIY and I always say if Kristi can do it, I can do it too. Thank you for being so inspirational to us all.

I second that emotion!!!

Okay, who are you? Who does this? Were you an Egyptian master builder in a former life? Is there ANYTHING you won’t try to build? You are one hella woman and my personal SHERO! YOU GO GIRL!!!

Wow! Didn’t expect this! I had thought you would do something with the 2 arm chairs that came with your table. Do you have plans for them? Are you building both at the same time or doing one at a time ? You should have a yard sale to sell off the things you decided not to use. Money for more projects.

Those are the ones that are currently flanking the buffet. 🙂 I removed the arms. I didn’t need or want arms chairs, but I wanted those two chairs to be different from the ones that I’m planning to use around the table. Those two chairs, in addition to having arms, were also just a tiny bit taller, so I removed the arms and upholstered them to go by the buffet. The other six match, and will be used for the table.

Oh ok. Didn’t realize they were the arm chairs. So you will have 8 chairs total around the table. You haven’t said but did you finish the table. Last you wrote about it you were trying to get the color you wanted and was using gel stain. How did that work out?

I still haven’t finished the table. I can’t make up my mind what I want. 🙂

Girl, you seriously need your own furniture line!

Great job, Kristi! Takes courage to do something like this … kinda like jumping off the dock and figuring you’ll learn to swim! You continue to inspire me and believe in myself to keep challenging myself to diy. Looking forward to learning how to upholster them!

I’m totally lost for words! You are a clever lady,there isn’t anything that you can’t do. Simply amazing. Wow!wow!

you are amazing…I admire so much the fact that you tackle projects that you haven’t done before.. you aren’t afraid of trying…and as far as I can see…you succeed…really gives me the inspiration to try things myself…thanks for not only the information and entertainment…but the inspiration….

I am impressed with your bravery, creativity, and all the ingenuity used for avoiding math and geometry. Congratulations! I would like to point something, with only good intentions. Pocket hole joinery is better suited in a stationary object (such as a bookshelf) than in a moving one or subjected to forces acting in different directions (e.g. chair). For a chair, mortise and tenon, dowel or other kind of joinery (+ glue, obviously), are stronger and resist in time. I know you are not a carpenter (neither am I), and I know that these are good for start, but it is a pity to work hard on these two chairs and have them fail in a few years if heavier people sit on them.

Pretty fascinating!

Add me to the speechless crowd. Just WOW!

Simply Amazing, as usual. I can’t wait to see the finished chair!

Kristi, you are so creative and energetic!

I read the comment about pocket hole joinery not being the best choice and as a retired shop teacher and woodworkper, I have to agree. People tend to shift their weight while sitting and a pocket hole joint might fail. You should check out the Beadlock Joinery system by Rockler. It’s cheap, easy, and makes really strong joints ideal for chairs. It is a mortise and tenon joint that almost looks like several dowels joined together side by side.ive used it several times and it’s a super fast method of reliable joinery.Also, i would consider adding some horizontal blocking in the wings for stability.

I’m sure the chairs have been upholstered and I can’t wait to see the final result!

PS…..please forgive my typos!

I hope you and Matt have a Happy Fourth of July!

Nancy

This is such a great tutorial. I’m taking the plunge to build my own chairs following this tutorial! What wood did you use for the frame?

Pine lumber from Home Depot