MDF vs. Plywood — Differences, Pros and Cons, and When To Use What

Lately, I’ve had several people ask me questions about MDF. What is MDF? How is it different from plywood? Why wouldn’t you just use plywood?

So today I want to share the differences between MDF and plywood, the pros and cons of each, and how I decide which one I’ll use on a project.

MDF – Medium Density Fiberboard

MDF is an engineered wood composite that is similar to particle board, but is much denser and stronger than particle board.

Imagine if all of the sawdust was swept up from other wood product manufacturing processes, and then that sawdust was mixed with binders and pressed into large sheets the size of plywood. Okay, that’s way oversimplified, and it’s not exactly the process they use to make MDF 😀 , but that gives you an idea of the makeup of the product.

Because it’s composed of such small wood fibers, there’s no wood grain in MDF. And because it’s pressed so hard at such high temperatures, there are no voids in MDF like you find in particle board. Here you can see the visible difference between particle board and MDF, with MDF on the top and particle board on the bottom.

Just like plywood, you can purchase MDF in different thicknesses depending on what you need for your project.

Advantages of MDF

- MDF is generally cheaper than plywood.

- The surface of MDF is very smooth, and you don’t have to worry about knots on the surface.

- Because it’s so smooth, it’s a great surface for painting. I recommend first priming with a quality oil-based primer. (Don’t use aerosol spray primers on MDF!! It just soaks right in, and is a huge waste of time and money. It will also cause the surface to become rough.)

- Also because of its smoothness, MDF is a great substrate for veneer.

- MDF is very consistent throughout, so cut edges appear smooth and won’t have voids or splinters.

- Because of the smooth edges, you can use a router to create decorative edges.

- The consistency and smoothness of MDF allows for easy cutting of detailed designs (such as scrolled or scalloped designs) using a scroll saw, band saw, or jigsaw.

Disadvantages of MDF

- MDF is basically glorified particle board.

- Just like particle board, MDF will soak up water and other liquids like a sponge and swell unless it’s very well sealed on all sides and edges with primer, paint, or another sealing product. Again, I recommend a quality oil-based primer. No aerosol spray primers!!

- Because it consists of such fine particles, MDF doesn’t hold screws very well, and it’s very easy to strip the screw holes.

- Because it’s so dense, MDF is very heavy. This can make it more difficult to work with, especially if you don’t have a helper who can help you lift and cut the large sheets.

- MDF can’t be stained. Not only does it soak up stain like a sponge, but also because there’s no wood grain on MDF, it looks awful when it’s stained. (Kind of like staining particle board. Why would you bother?)

- MDF contains VOCs (urea-formaldehyde). Off gassing can be greatly minimized (but probably not eliminated) if the MDF is encapsulated with primer, paint, etc., but care needs to be taken while cutting and sanding to avoid inhalation of the particles. I recommend cutting and sanding outside while wearing a particle mask.

Plywood

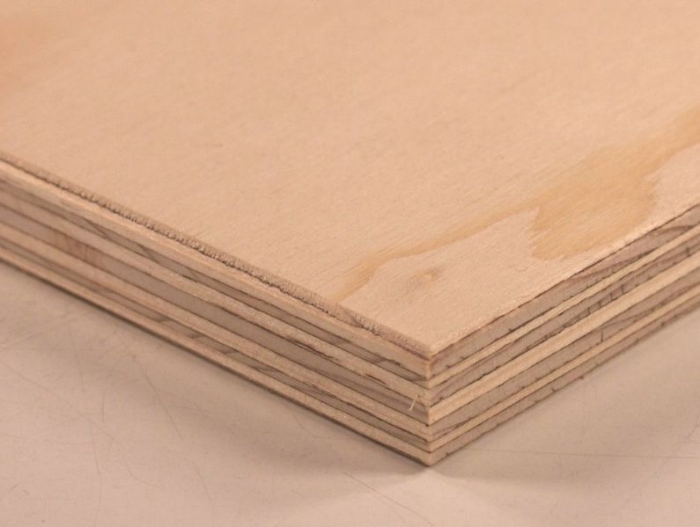

Plywood is also an engineered wood product that is made by pressing and binding sheets of wood veneer together into one solid piece.

Plywood comes not only in different thicknesses, but also in different grades, so you can choose the right one for your project. Lower grades are used in construction of houses for subfloors and such. Obviously these types of plywood don’t need to look pretty since they’ll be covered up.

The higher grades of plywood (stain grade, cabinet grade, etc.) are much prettier and smoother. They have consistent wood grain showing, and generally lack knot holes or other major imperfections. And cabinet grade plywood is always sanded very smoothly on the surface.

You can also find plywoods in various wood species, like oak, or maple, or pretty much anything else, so that you can get exact look you want for your project.

Advantages of plywood

- Because it consists of layers of wood veneer with the grain on each layer running a different direction, it’s a very strong building material.

- It’s less susceptible to water damage than MDF, and won’t soak up water and swell as quickly or easily as MDF does.

- It’s stainable, which makes it perfect for kitchen cabinets, table tops, and other projects where you want a large stained wood surface.

- It holds screws very tightly since the varying grains of wood on each layer give the screws something to hold onto.

- While most plywood does contain urea-formaldehyde and other VOCs, it is now possible to purchase plywood without formaldehyde. Look for the Purebond brand at Home Depot.

Disadvantages of plywood

- It’s more expensive than MDF. And obviously, the higher the grade, and the more special the species of wood, the more expensive it gets.

- Because of the layers that show on the edge, you have to finish off the edges somehow. This can be done with iron-on edge banding or with pieces of lumber or decorative molding.

- Plywood will often splinter on the edges when cut, so it’s harder to get a smooth cut with plywood than it is with MDF.

- It’s more difficult to cut detailed designs into plywood (scrolled, scalloped, etc.) because the edges will splinter, and then you’re left with edges that show layers and might possibly have voids in some places.

- Like MDF, most plywoods contain urea-formaldehyde and other VOCs which can off-gas into your home. Take precautions while cutting.

How I determine which one to use:

Actually, we’re going to do this “pop quiz” style. Are you ready? Don’t be nervous! There will be no failing grades handed out in this class. 🙂

For this project, I needed something that I could use my jigsaw on to cut out a detailed, scalloped design. I needed the entire thing — surfaces as well as all cut edges — to sand perfectly smooth. I knew I’d be painting the table (or covering it somehow), so staining wasn’t a consideration.

So which one would I use for this? Plywood or MDF?

2. The bottom shelf on my coffee table ottoman.

I obviously needed a large, smooth surface for the shelf, but the main consideration here was that it needed something that could be stained to match the other wood components of the coffee table base.

So which one would I use for this? Plywood or MDF?

3. Scalloped decorative mirror

I needed to use something in which I could cut a detailed, scalloped design and be left with smooth edges. I knew I would paint this piece, so staining wasn’t an issue.

So which one would I use for this? Plywood or MDF?

4. The upper bookshelves on my built-in bookcase wall

I needed something strong for building. Since I would be painting the whole thing, staining wasn’t a consideration. I also knew that I would be covering up all of the edges with trim, so that wasn’t a consideration either.

So which one would I use for this? Plywood or MDF?

Answers:

Are you ready to see how you did on your quiz? 😀

1. For the scalloped console table, I used MDF. It’s paintable and smooth. The smooth edges allow for detailed, scrolled designs to be cut. And the edges sand smoothly as well.

2. For the lower shelf on the ottoman, I used plywood. Plywood is stainable, where MDF is not. I covered the not-so-pretty edges with pieces of 1″ x 3″ lumber.

3. For the scalloped mirror, I used MDF, for all of the same reasons as on the scalloped console table. (FYI, this also could have been made out of 1″ x 4″ lumber, cut into four pieces and mitered in the corners to make a frame. Then the scrolled design cut on the inside edge of that frame. The benefit of the MDF is that there are no mitered corner seams, and no extra work piecing together a frame.)

4. This was a trick question. 🙂 I actually used MDF on this project, but plywood would have been perfectly acceptable, and actually it would have been preferable. If I had been building bookshelves that sat on the floor, where the edges might be susceptible to spilled water or even floods from plumbing issues, I would have definitely used plywood. However, with these being just on the top, away from the floor, I used MDF to save money.

So how did you do?

If you have any questions regarding MDF vs. plywood, I’d be happy to answer them for you if I can!

Addicted 2 Decorating is where I share my DIY and decorating journey as I remodel and decorate the 1948 fixer upper that my husband, Matt, and I bought in 2013. Matt has M.S. and is unable to do physical work, so I do the majority of the work on the house by myself. You can learn more about me here.

![How To Wood Fill, Sand, Caulk, and Paint Trim — My Process and Preferred Products [VIDEO TUTORIAL]](https://www.addicted2decorating.com/wp-content/uploads/2019/09/how-to-wood-fill-sand-and-caul-wood-trim-thumbnail.jpg)

Since you mentioned the condo, are you planning to finish it off and sell? I imagine it will be handy to hold on to it for now until you get your foundation fixed and once you get it finished and sold move into the house for good. Just wondering and anxious to see how it turns out in the end with the last bedroom and living area.

We’re definitely going to sell it. We’ll put it on the market as soon as I can peel myself away from house projects and go over there to finish up some projects that need to get done before we put it on the market. 🙂 I SO don’t want to work on the condo. It’s like taking 20 steps backwards. But it needs to get done. 🙂

What is the problem? Do you want to sell it or not?

You do realize you’re responding to a comment that was made THREE YEARS AND EIGHT MONTHS ago, right? Evidently I’m not the one with the problem. And that condo has been long gone.

How do larger pieces (like your new console table) hold up with glue and brad nails? I’ve only ever made small-scale items with MDF, so I’d be curious to know how well it does when it has to support more of its own weight.

You could not have offered this at a more perfect time for me and my project. I’m refurbishing a table from Goodwill that I fell in love with. It’s a round pedestal table with a large leaf included. The table was slightly water damaged on top, but I thought it could easily be sanded out. I THOUGHT this table was all wood, but have found that it must be MDF–what I kept calling particle board. After attempting to sand it down, I found my error because after the veneered top, I was sanding into what seems to be MDF. I’m still using this as a practice piece in Annie Sloan chalk paint (tiffany color) and it looks great, except for the top that is not completely smooth. My plan is to go ahead and lacquer the top and get a glass piece to cover it. Would you recommend doing this?–other than the slight water damage on top, it looks wonderful. On closer inspection, I can see underparts that should have tipped me off on this not being all wood, but it’s very hard to pick out on this piece. Lesson learned!

You might try using Zinsser primer on it first. Even though you’re using chalk paint, one of the great things about Zinsser primer is that you can put a couple of coats on, let it dry thoroughly, and then use fine sandpaper (220-grit) to sand it very smoothly. That might help eliminate some of the roughness of the MDF that is exposed from the sanding.

I do think covering it with glass is a good idea. Not only will it protect it, but it’ll also make it look like a higher end table. 🙂

Brent, I try not to make really large items with MDF if the piece of MDF will be horizontal, like shelves, table tops, etc., because MDF will certainly bow over time, much more so than plywood will. So you have to be really sure that you’ve braced the edges really well in order to keep it flat. And the larger the piece, the more likely it is that you’ll need to add support underneath it as well.

In fact, even on the shelves on the built-ins at the condo, just the weight of the MDF alone made those shelves bow until I added support in the back (quarter round under the back edge and nailed into the back panel) and the 1″ x 3″ lumber on the front edge. (And I always use real wood lumber for supports like that — not MDF boards, even though they’re cheaper, cut straighter, and look just like wood lumber.) Once those supports were in place, those shelves were incredibly solid and sturdy. I’d be confident putting a set of encyclopedias on them at this point. But they were also only 12 inches deep. I’d hesitate to go much larger with MDF.

So you definitely have to keep any horizontal pieces somewhat short and/or narrow, and you have to be very certain that they have support on the edges that won’t allow them to bow.

My console table is pretty wide (64 inches), but it’s only 14 inches deep, and it has vertical pieces supporting it all the way around. Even though those vertical pieces are nailed into the edges of the top, rather than supporting from underneath, It’s still very sturdy and secure since it’s nailed and glued.

But as far as the glue and nails, I always, ALWAYS use Gorilla Glue wood glue on my projects. I have a ton of confidence in that glue, and it hold incredibly securely. Once it’s dry, I never worry about my MDF projects falling apart.

So that’s the long way of saying, I try to keep MDF pieces somewhat small unless I’m adding tons of support, because on it’s own, it’ll definitely bow and bend over time (and it doesn’t take long for MDF, either).

Do you use nails with MDF? How do you secure 2 MDF boards together?

Lisa, I always use wood glue (Gorilla Glue specifically) and then finishing nails in my nail gun.

You can use screws with MDF, but just be very careful not to strip the screw holes. I also like to pre-drill the holes, and then add a little wood glue into the hole (or on the screw) before screwing the pieces together. That just makes it a little more secure. And of course, I also add wood glue to the two pieces that I’m securing together.

There are a variety of screws designed specifically for MDF. I have used them with good results.

Thanks Kristi. That cleared up a couple of things I wanted to ask before but didn’t. I ‘aced’ the quiz and surprised myself.

Great teaching moment. I’ll definitely remember your advantage comparisons.

What a great informational lesson without be to “techy” for us. Thank you!

Oh my word, best article ever. Please consider teaching whenever the opportunity arises. You’re so good at it!

I hate going into Home Depot and feeling like an idiot. An article like this gives me so much confidence. Thank you!

Great informative article, Kristi!

Hi Kristi! I have a big question for you… we are going to be refacing our kitchen cabinets this year with new shaker style doors. They will be painted (we can prime them first) – and I am not sure which would be better – MDF because of the smooth edges, or a nice maple plywood. Your thoughts??

Thanks!

Krista

I would stick with plywood for cabinet doors. Plywood doors can take the wear better than MDF, and they’re lighter so they’re easier on the hinges.

Great article, Kristi. and, thanks for the sneak preview of the primed console table!

You actually can stain MDF. The TLC program Trading Spaces used MDF by the truck load. They would paint or stain according to the decor. It takes a talented hand but with the right touch you can even give it a grained look.

It’s possible, but it’s not pretty. 🙂 You can do some sort of faux treatment on it with paint, though. But just keep in mind that those things on Trading Spaces were built quickly and cheaply, and we never saw them up close and in person. I’ve read horror stories from some of the homeowners who had their homes “decorated” on that show.

Thanks for the explanation. I had no idea about all the variables to take into consideration. Sounds like a little planning will save some heartache (and blisters!) down the line.

Kristi, this was a GREAT explanation. I have used both too and for many of the same reasons you mention – I like MDF because it’s smooth and straight and I get much better accuracy/smoothness when cutting, but it’s also heavy and very “processed”, exactly all the features you mention. Great examples of when you would use one or the other. You are my DIY idol! 🙂 Sharon

Haha! Thanks, Sharon! 😀

I love your blog and have been following for such a LONG time! I did just want to throw out there that we used MDF for a countertop in the basement craft area, even around a sink! if you seal the mdf with a mix of glue and water (you must apply this to all sides as poly alone just soaks right in!) then using a foam roller apply like 5 coats of poly you actually get a really great finished product! my hubby did router the edge with a chamfer bit and i love the contrast of the dark brown (the color it gets when it’s sealed) and the bright white cabinets.. A major fail for us was trying to use MDF for a radiator top. I thought, ‘heck, it’s going to be painted so it’ll be sealed” but when the steam rises, it curls up even though it’s had multiple coats of paint and sealer. Next time i’m going w/ solid wood for that! Keep blogging– i’m so inspired that I’m actually going to try upholstering– love that ottoman!! Thanks!!

Thanks for that info, Sue! I’ve never heard of sealing it with a glue and water mix.

Thanks for that informative tut. It all makes sense! So now I know what kind of sheets to buy and how to prime. I think I would have primed the MDF with aerosol primer, glad I know that’s not the right way. On a flip I did in San Antonio, I used MDF for the floor and door trim. It was beautiful (wide) and pre-primed. I’m thinking it was about 4″ wide and had a really nice scalloped (?) outside edge.

Yep, they make quite a bit of trim out of MDF these days. I love it because it’s so consistent from one piece to the next. You don’t get that consistency with real wood trim. The drawback, of course, is that it isn’t water resistant unless you prime it on the edges and backside before installing it (which I never do), so if you have a plumbing leak, it can ruin your baseboards. I learned that the hard way. 🙂

Good point! Hope the new owners of my flip keep the water off the backside! I didn’t prime that part. Uh oh…

What an awesome site, being a DIY’er myself it is awesome to see other peoples dreams come to life. It is a unique gift to have to take someone elses cast offs and give them a new life.

I look forward to many more and possably sending you some pics of my own creations!

This is a great instructional primer on sheet goods, Kristi. I’d like to add a couple of things, if I may. Another type of plywood that is great to use is Baltic birch. It comes in different thicknesses, but is usually just available in 69″X 60″ sheets. It has absolutely no voids, and the layers of veneers are all the same thickness, so the edges are often left exposed. They have a kind of striped effect (you’d like them!) and are quite attractive.

For using MDF as shelving, it will not hold as much weight as plywood or solid wood without bowing, so they should either be shorter, or have more vertical supports, or have reinforcement on the front and back edges. WOOD magazine had an excellent article on shelves.

Sorry—size of Baltic birch should be 60 X 60.

Great post! I’m using MDF for the first time on my design wall. As a quilter, I need to block my art pieces and MDF is able to accept straight pins. Wonderful product.

This is the most informative DIY blog I have ever read, and this is the best post you have ever written. I forwarded it to my husband, and even he was blown away by the sheer amount of info it contained.

Had to shake my head at yesterday’s (actually, tomorrow’s) post about the morons visiting your blog. Please don’t stop blogging! I daresay that the gratitude felt by myself and many others totally grinds their small-mindedness into the ground.

You know, MDF is inexpensive, durable, and a good choice for many woodworking and carpentry projects. MDF is commonly used for shelving in closets and cabinets because it’s inexpensive and smooth. When I use MDF shelving for heavy loads, I simply beef it up with wood. Although medium-density fiberboard furniture isn’t of the same quality as solid wood furniture, it is cost-effective, often environmentally friendly, and incredibly durable. While painting it never use a water-based product for the initial finish coat. The only real difficulty that arises when painting MDF is what to do about the edges, which are more porous than the surface — similar to the end grain of lumber — and drink in most of the finish. I use drywall compound to fill the edges, whether they are cut squarely or shaped with a router bit, and I apply the compound liberally with a finger or with the palm of my hand.

Wait.. what do you mean durable? My experience with mdf is that it dings and chips VERY easily. I’ve noticed this in peoples houses and can spot MDF very quickly.. What do you do to harden it?

MDF weighs a ton,and the dust is horrible,you get dirty when you work it.Plywood is a lot lighter,cleaner,and smells better,and holds screws,nails,dowels,better.Plywood would repair better.MDF has it uses but for cabinets i would choose plywood,cost wise it isn`t that much more.

Its a great informative article.Thanks a lot.

I was planning to use mdf for scalloped Round mirror frame (30 inches diameter) What should i use to hang it on the wall? i was thinking about using hooks but you mentioned that screws don’t hold well on mdf.. any alternative?

I would use an Ook Hangman French Cleat, available at Home Depot and Lowe’s, or online.

some good info., but -“Imagine if all of the sawdust was swept up from other wood product manufacturing processes” – no- imagine carefully selecting and processing wood fibres for the specific qualities needed in the final product, then pressing them together, under controlled conditions.

Also there are special screws for holding in mdf – confirmat is one example – though they may be hard to find.

Which one is the best to use in a wrought iron bed ?

I bought a bed 6” X 5″ and need to put a something to cover it up,before putting the mattress .

Thanks

I would use plywood.

Thanks for the prompt reply. Really learned some good stuff from the article.

I think you mean 6′ x 5’… otherwise that’s one tiny bed! 🙂

Hey . I wanted your opinion on a project I was considering on trying . I want to build one of those princess castle beds for my daughter . Websites that are selling have said they use mdf . Which makes sense considering the edges and designs at the top . But I’m worried about it being too heavy and not being able to stay up and sturdy . What do you think ? Also would it be ok to use both ? For instance plywood for the main building of it and then mdf at top of the castle towers for the designs ?

I would use both, depending on where I needed strength, and where I needed a super smooth finish.

Hey, my husband and I are making a loft bed for our son and are trying to decide whether to use mdf or plywood as the platform sitting on top of cinder block for his bed. I will also be attaching material around the platform for the tent area under the bed. We want something strong and smooth. I know the mdf is smooth but what would you suggest?

I would use plywood for that.

I am planning on making a built in wardrobe for the bedroom and initially thought of using MDF. The dimensions are:

96 inches (height), 30 inches (width), by 24 inches (depth). Would you use MDF for a project like this? Any thoughts would be much appreciated. Thanks! 🙂

Yes, I think MDF would work just fine for a project like that.

Thanks for your quick reply! I’m new to all this so have another question, if I may?

I’m planning on just one large wardrobe door that will be 96 inches by 30 inches. Would you use 1/2 inch thickness of mdf or would 3/4 inch be better? I’m hoping that the mdf door won’t bend with the weight? What are your thoughts? Thanks so much! 🙂

Hi. I’m an Industrial design student and i’m working on a project abt bending MDF. I was wondering if you could give me some sources and information abt the subject? And how can i persuade the audience that MDF is better than wood? ‘Cuz this project is a something huge and I need a great proposal! Thank you!

I think you’d have a hard time convincing people that MDF is better than wood across the board. Whether or not it’s a better choice than wood completely depends on the project it’s being used for.

As I said it’s mostly about a technology that can bend MDF into small radius.. So in general I’m trying to say why bending woods and not bending MDF so that less trees are being cut off..

Thank u for the quick reply!

As you mentioned MDF is great for painting and for building shelves.

It is also very heavy as you mentioned. One other drawback is that when you cut the stuff it is very dusty and makes a big mess so be prepared to tarp off all of your existing furniture or equipment that needs to be covered before you start cutting.

http://Www.skillfulhandyman.com

I’m going to have closet organization system built in the walk in closet, the guy wants to use MDF. I’m not sure how strong or duratible it would be so he suggested ACX sanded plywood. What’s your thoughts? I have a ton of clothes and shoes don’t want my hanging clothes to cause it break. Help!

If he’s experienced and knows how to work with MDF, and how to reinforce the shelves so that they’ll hold lots of weight, then it will be fine. The key really is the experience of the builder, rather than the choice between MDF and plywood. You can get a very sturdy, well-built, high quality storage system out of either one, as long as the builder knows what he’s doing. If he doesn’t know what he’s doing, then you can get structural failure and weak shelves regardless of whether MDF or plywood is used.

MDF does hold screws quite well from the face surfaces but you should never try to screw into the sides as it just splits open. It is more like layers of brown paper glued together. Very stiff and lays flat.Predrill holes 50/60% smaller than screw diameter.

I am seeing pool tables made with MDF and some with plywood. Which is better, of the two, for pool tables?

I don’t know for sure, but I would imagine that they would be about the same. I couldn’t find anything comparing MDF and plywood, but I did find this: https://www.libertygames.co.uk/faq/answer/mdf-vs-slate-pool-tables/

Can I use 3/4″ MDF as a sub top for my bar? I only ask because I’m not sure it will be as strong as plywood. I would only be using it for the sub top, not the finished bar top.

I would personally use plywood for something like that.

Thank you! This is the most helpful and detailed information I found in clear lay-person’s terms. It wasn’t condescending nor oversimplified, just exactly what I needed to know. As far as I can tell from the annoying other places I’ve looked in my research, it’s also accurate. The pictures just make it perfect. Thank you!

Thank you so much, kristi. This is like voila!!!! i got the answer!

Anyway, i will like to know MDF and plywood? how much friendly are they to earth? and is bamboo an on coming choice? Skateboarders are starting to use bamboo for their performance stun. Anyone?

I am almost done making a herringbone coffee table with redwood glued down to a MDF base (based on a tutorial I found). I came across this article and am kicking myself for not going with plywood.

Since my project is almost finished, do you have any recommendations for reinforcing the mdf base so it doesn’t bow over time?

The table is roughly 4’x2′, and I’m planning on using hairpin legs. Thank you!

The best thing you could so is edge the table top with real wood lumber, like 1 x 2’s or 1 x 2’s, attached vertically around the edge. That will keep it from bowing and will also give your edges a finished look.

hi. I am considering designing a tiny home and am wondering what to use for the floor. I am thinking plywood but not sure how thick.

You’ll need to check with your local building codes. The type and thickness will be specified by local codes, and is not universal.

Namaskar

Thank you for the amazing read.

What material should we exploit for:

1) Closet- wall to wall, floor to ceiling

2) TV Unit

Regards

Love & Light

Piyush

I am planning a 9ft high painted bookcase with base doors. The uppers will contain three sections with shelves. The middle section width will be 34 inches. Want a smooth, clean finish, but also want to be able to support heavy art/history books. MDF or Plywood? Thanks!

Hi Kristi … I’m starting my first project thanks to your inspirational blog! I’m building a laundry room storage cabinet. The shelving is going to be very deep ( 32 ” deep by 24 ” w) I don’t have to build the shelves to be as deep as the space but storage is always needed so why not use all the space, right? I was wanting to do adjustable shelving but now I’m concerned that the size of the shelves is too large for adjustable shelf pins to support it. What do you think?

Making the change from carpet stairs to hardwood. To save some money I plan on buying a sheet of wood, measure and cut up for my risers. What would be the ideal wood to use for my risers (will be painted white)?

Thanks in advance

The difference in MDF and plywood was very informative. We are about to start making a kitchen. This will really help

Thank you so much Kristi, Matt and Boo..

I am planning to buy a bedroom, actually bedroom made of MDF are little bit cheaper than solid wood, my questions are: is it good idea to buy bedroom made of MDF? is it safe for health? because I heard that some particles will fly on the air from MDF and they are harmful. and lastly does the bedroom last?

please help me because I am palling to buy one soon

Hi. Are MDF boards strong enough to hold a mounted 46″ tv?

Thanks.

No, you should use solid lumber for something like that.

We were planning to use MDF for the baseboards in our basement buildout but discovered some moisture problems which we are addressing. However there was an indication of mold on several pieces of baseboard we had already installed.

My question is can you clean the mold off the MDF and reuse? if so what product would you use?

I would replace rather than reuse. MDF is very porous, so if there’s mold on the outside, there’s probably mold spores within the MDF that can’t be cleaned off.

Thanks for sharing awesome tips!

The information is very helpful Kristi! Not to mention with the quiz, they help me understand more about the differences and their applications! Thanks for the article =)

Can you stain MDF with water-based stain?

You can stain MDF with either oil or water-based stain, but it’s not pretty. But then again, I guess that’s subjective. And it might swell a bit, especially with the water-based stain.

What about priming? Can you prime with water based paint or is oil primer better?

I would only use oil-based primer with MDF.

Hi Kristi

I’m at the beginning stages of planning to build cat condos for my new cat boarding business. What I plan to build are essentially large boxes stacked two high and open on the front and back sides. The backside will be facing a window and the front will be a plexiglass door. I’m trying to decide between using plywood or MDF. They will be primed and painted on all sides. Any guidance you can provide will be much appreciated.

Since cats don’t weigh very much, and you’re planning on priming the whole thing (with oil-based primer, I hope), then either one would work. My one and only opinion on the matter would be that since you’re going to be boarding other people’s cats, and some people are very particular about chemicals and contaminants and such that their family members (including pets) come into contact with, it might actually be beneficial (and perhaps even a selling point in advertising) to use formaldehyde-free plywood for construction. Regular plywood and MDF both have chemicals in them that a lot of people are sensitive to, but if you use PureBond plywood from Home Depot (Lowe’s may also have it) then your customers might really like that. And since PureBond plywood is cabinet grade (meaning, it’s actually very pretty), you might also consider not priming and painting it, and just sealing it with a low- or zero-VOC water-based polyurethane.

Hi Kristi,

Thanks for the great article and for still responding and commenting 4 years later.

I want to build sliding closet doors. The rails have already been installed on the ceiling (2 rails), with no space between them so the doors have to be no more than 3/4 maybe 1 inch of thickness.

I am really not sure what to use, MDF or Baltic Birch Plywood. I am afraid the plywood will eventually bend. Will the MDF also eventually bend?

What’s your take on that?

Best regards,

Xuan Ixtop

I would use plywood just because it’s more durable and can take the daily wear and tear better. I don’t see why it would bend or warp, unless I’m not understanding how you’re going to use it. Plywood is stronger than MDF, though.

Hi Kristi,

Great post! Very helpful as there’s so much out there about MDF vs. Plywood that it’s hard to know what to trust. Quick question – we are remodeling the top floor of our condo and going for a very modern look. As such, we’re talking to cabinet makers about options with MDF – one of them is also proposing an option where MDF is used for the cabinet box rather than plywood. Drawers and sliders will be maple dovetail construction, but the actual box will be MDF. What do you think?

Thanks!

I personally think it’s fine. The only thing to keep in mind with MDF that will touch the floor is that it wicks water. So if you’re using it in an area that will/can get wet, I suggest sealing the edges and areas that will be close to the floor.

Hi Kristi,

I am ordering $6,000 worth of new cabinets for a kitchen remodel – the kitchen is very small. The manufacturer is American Woodmark and the MDF is standard for the cabinet box, whereas if I want to use all plywood it would add about $1,200 more. The house will be in the Lake Tahoe region and it is not a humid area. Is there any downside to using MDF? Is there any advantage to using plywood for the cabinet boxes? Price is not a huge issue, but I don’t want to waste my money on something unnecessary either.

Thank you,

Linda

MDF is very strong, so in that regard, MDF boxes are just fine. The only possible issue I can see with using MDF boxes in the kitchen is that kitchens see more liquids than other (non-bathroom) rooms — spills, possible plumbing leaks, etc. And when you have unsealed MDF edges sitting on the floor and something spills or water leaks, those unsealed edges will, without question, wick the water up into the MDF causing it to swell and weakening it. I would ask the company if they seal the edges that are going to be against the floor. Even if they don’t, that doesn’t mean I’d rule it out. You’d just then have to consider how messy you are in the kitchen, and how likely you are to have big spills that seep under the cabinets. If it’s unlikely, then MDF should be just fine. I personally wouldn’t have a problem with MDF boxes in my kitchen.

Kristi,

Some insights from a recent project for my sweetie: a set of angled shelves built into a closet, to hold her stock of mat board (for framing.) I needed strength, clean smooth surfaces, very flat, and cheap. Solution: sheets of white melamine (particleboard with white melamine veneer.)

The biggest challenge was that I had to install all eight shelves before installing the left-side support or the left-footed support. How to install ~3×4 ft sheets of heavy material only really supported on the upper back and angled right sides, and a few inches on the front right?

The magic solution: modern construction adhesive and placeholder screws. That stuff is unbelievably strong, with about a 15-30 minute working time. I didn’t need it for this project but many of these adhesives can even bond frozen lumber.

Now I understand how they can build homes in the wet and ice here.

Hey 🙂 I love your information. Thank you.

Question: If I wanted to do yarn art on wood that is 18 mm would mdf be an acceptable choice?

Yes, MDF would work for that.

Hi Kristi,

Found your article extremely informative. Thanks for writing it in such easy-to-understand manner.

I have one question. Can we paste Decorative Laminate (1mm) easily on MDF? Will it hold?

Yes, you can use MDF as a base for decorative laminate. That’s usually adhered with an adhesive like rubber cement, and since MDF is very porous, it might take more than one application of the adhesive before it’s sticky enough to apply the laminate. Be sure to read the directions on the adhesive for using it on porous surfaces.

My mattress is too soft and it is just kept on the slats, so thinking of adding a firm support between slats and king size mattress. Which one would be better MDF or plywood?

Plywood

Thank you! that was quick 🙂

I am making closet cabinets, connecting the face frame to the sides using a glued tongue and groove joint.

The face frame will be wood

The sides will have the tongues cut on the edge and I am concerned that they will be weak using MDF.

Question;

Is it better to use veneered MDF or veneered plywood for side boards

I’m having a hard time envisioning what you’re talking about, but my general rule of thumb is this — either MDF or plywood can be used for any parts that are fixed (i.e., won’t move), like the actual cabinet boxes. Anything that moves needs to be made out of solid wood or plywood (i.e., cabinet doors). MDF is heavier than plywood, so while it can be used for cabinet doors, it’s not something I’d ever choose. Plus, it gets dinged and scarred easier than plywood.

Thank you. I think I am gonna go with regular old fashioned Maple plywood

John T

Very informative article.

Am building a full wall bookshelf.

Was thinking of having a plywood base (so that mopping water will not damage) and remaining all components (vertical walls, shelves, backboard, etc) MDF.

Do you think that’s a good idea or should I go full plywood?

I personally think that’s fine. I’ve built many bookcases, bookshelves, and cabinets out of MDF, and they’ve all turned out great.

Having a huge room addition built for walk-in closet and just told the guys to go ahead with MDF vs partical boards for the shelves and cubbies. Now reading and worried that hanging rods if MDF doesn’t like screws and chips and smells may have been a bad decision!

I am in the process of building cabinet-style closets out of MDF. Yours should be fine.

Hi. I’m changing my flat panel kitchen cabinets to shaker style and can’t decide between 1/4 inch plywood or mdf. I will be painting the cabinets. What do you suggest?

I’m trying to envision what it is you’re doing. You’re cutting out the middle of a flat panel door and adding a panel to the back? If that’s the case, I’d use the material that more closely matches the current material. If the current material has visible wood grain in it, then I’d use plywood. If the current material is completely smooth and has no visible wood grain, I’d use MDF.