How To Build A Small Portico Above A Door – Part 1 – The Basic Frame

Yesterday I started working on the portico to go over the side door of the studio. These are the two that I chose to use as my inspiration.

This is the first project I’ve done in about four weeks because of the back, shoulder and arm issue I’ve been nursing. It felt so good to get back at it, but wow! Did I choose a doozy of a project to jump back in with!

The building process was actually pretty easy (so far). The installation of the top parts was challenging (mostly due to the fact that I’m only 5 feet tall), but I finally figured out the solution. I pulled my truck as close to the door as I could safely get it and set up my 8-foot ladder in the bed of the truck.

😀 That’s probably not an OSHA-approved method. 😀

But working out in the heat and sun just about did me in. I’ve been sedentary in my air conditioned house for the last four weeks, so actually having to break a sweat, staying out in the 100-ish weather for hours on end, and working directly in the sunlight about half the time was almost more than I could take. But I pushed through, and I got all of the basic frame for the portico cut and put together.

So let me show you how I got to this point…

I’ve ordered some large traditional style brackets (found here) to use on this portico, and they measure 24″ x 36″.

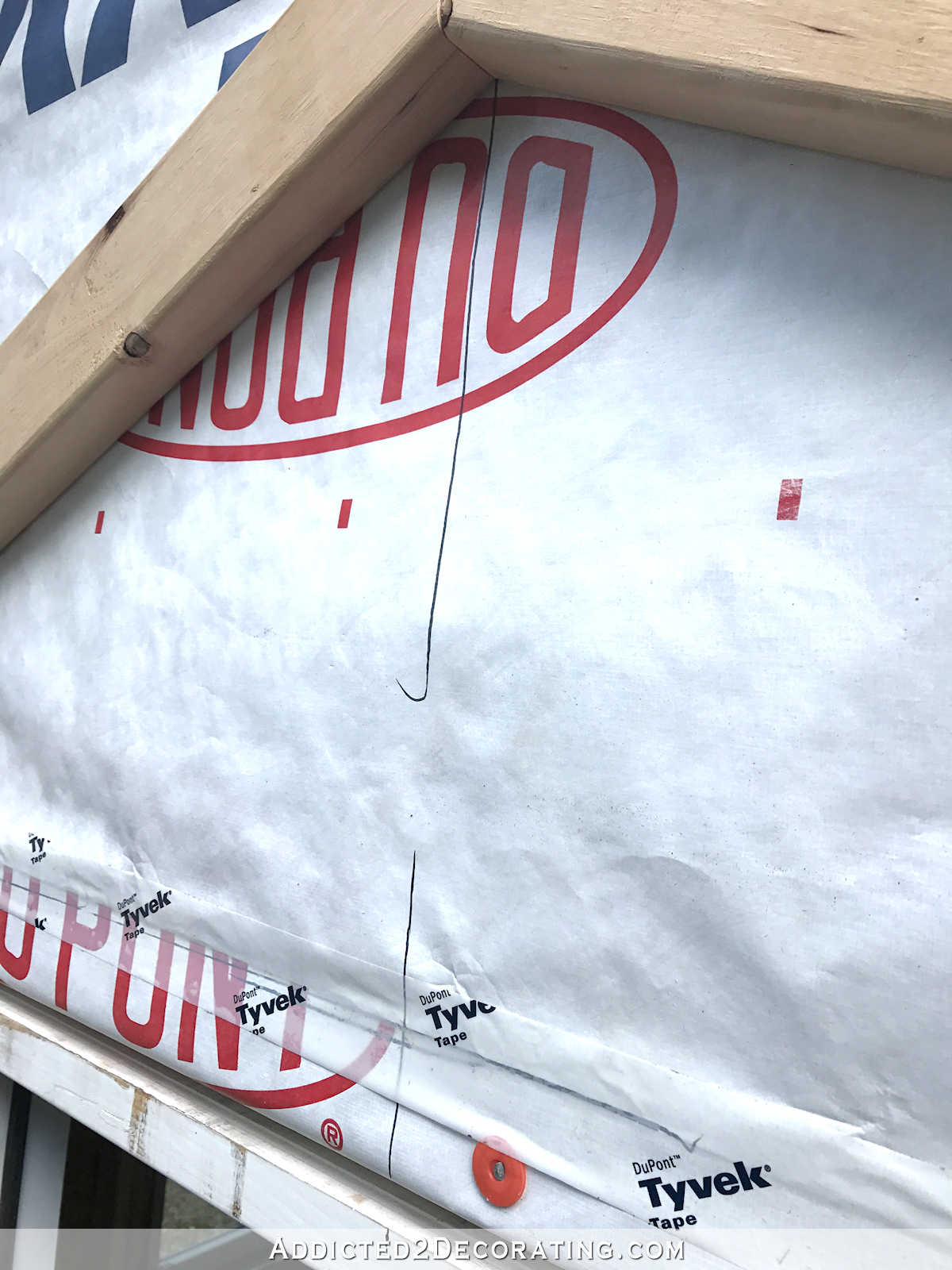

But since the portico needs to be built before the siding goes on, and the siding will be installed this week (hopefully!!), I had to work around not having the brackets in hand just yet.

So I built some brackets out of 2 x 4’s, and I made them so that the inside measurements are 25″ wide and 37″ high. I cut the top piece 26.5 inches and the long piece 37 inches, and then screwed them together using 3-inch deck screws in this configuration with the short piece sitting on top of the long piece…

Next I cut another piece with 45-degree angles on both ends. This piece, on the long side, measured 32 inches. This piece is temporary on my brackets. When my pretty brackets get here, I’ll just remove this diagonal piece and slide the pretty brackets in there in its place.

Then I predrilled two holes on the long piece and started two deck screws in the holes.

And that bracket was ready for installation. I had already marked some lines on the house so that I knew exactly where I wanted to put the brackets (12 inches from the inside of the door jamb). I held it up to the marks and screwed it onto the wall. Since I had already started the screws in the holes, this process was very easy.

And then I repeated that whole process with the second bracket. The only difference is that when installing the second bracket, I didn’t just rely on my marks. I also used a long board sitting on top of the brackets with my level on top of the board to be sure that the brackets were level with each other.

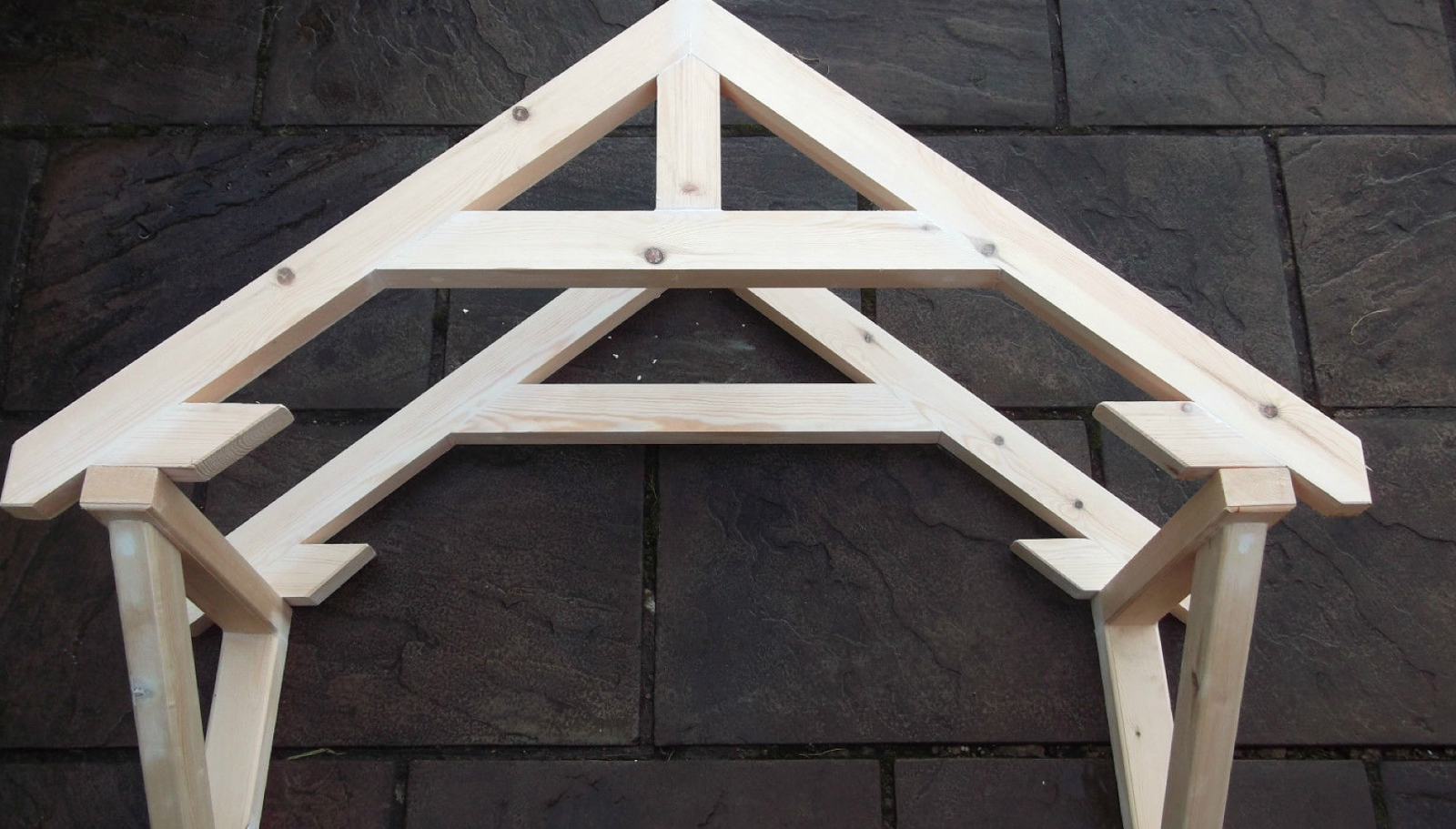

With the brackets installed, I was ready to move on to the two little trusses. This was a bit more challenging just because it involved some math, and my brain doesn’t like math. 😀

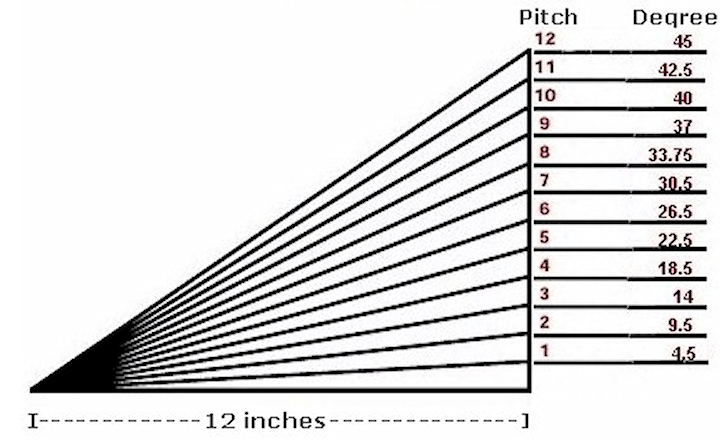

The first step was to figure out the pitch of my roof. Pitch is simply the number of inches that the height of the roof rises in a 12-inch span. So I used my level to draw a horizontal line (1). Then I picked a random spot and used my level to draw a vertical line (2). And finally, I measured over 12 inches and drew another vertical line using the level (3). Then it was just a matter of measuring the length of both vertical lines and figuring the difference.

I was a little confused because my short line was 6 5/8 inches, and my long line was 12 inches, which means that in a 12-inch span, the height of the roof rises 5 3/8 inches. Chuy (the project manager on my garage conversion project) said that I could go with either a 5/12 pitch or a 6/12 pitch for my portico, but he said that my house looked more like a 6/12 to him. So that’s what I went with.

And with the magic of Google and the help these nifty charts available online, I found that the angle needed to create a 6/12 pitch is 26.5 degrees.

So I cut an 8-foot 2 x 4 in half, and then cut one end of each board with a 26.5-degree angle and screwed the two boards together using three deck screws. With the first truss roughly put together, I tested it by setting it on top of the brackets…

I had marked and measured the middle of the door so that I knew exactly where the peak of the truss needed to go.

Once I had the truss in place, I used a pencil to place marks on the truss right where the outside of the brackets met the truss. I did that on both sides.

I transferred that mark to the face of the board at a 26.5-degree angle. If your miter saw has a laser guide, you can use that laser line to know where to draw the line at that angle. Then I measured and cut the board 4 inches from the pencil line using the same angle. I repeated that on the other side.

Next, I measured up on that same line 1.5 inches and placed a mark. Then I repeated that on the other side.

And then using a long straight edge (i.e., a 1 x 4 board), I lined up the straight edge with the marks I just made and drew the horizontal lines.

And using my jigsaw, I cut along the lines to make these cutouts that would sit on top of the brackets.

After finishing the cutouts, I tested each truss to be sure the fit was just right.

Next I determined which truss would go in the front (since it’s visible, I wanted it to be the nicest). I cut a spacer 2 x 4 to 23.5 inches long, and I screwed the spacer to the back of the front truss as close to the peak as I could go. Then I set it in place, making sure each truss was exactly where it needed to be (I designed this so that the front truss sits back one inch on the bracket…just because I wanted to), and then I used a pencil to trace around where the 2 x 4 hit the back truss so that I’d know where to screw them together. It didn’t exactly match the placement on the front truss because 2 x 4’s can be a bit twisted and imperfect, even if you try to find the best ones.

I didn’t actually screw the spacer to the back truss yet. There are still a few steps that need to happen before I do that. So this is where I stopped for the day.

It’s still a bit rough, but there are several more steps and lots of finishing that needs to happen before this portico can be called finished. But at least we can see the general shape coming together. I think I’m going to love it!

UPDATE:

The portico is finished! Click the links below to see the other posts on this project.

Scaffolding!

YES!

I don’t have scaffolding, and I wasn’t going to spend the time and money to buy or rent it just for this small project. My truck worked perfectly. 🙂

Love the portico! But please please never climb on a ladder in the back of a truck! My boss (who was an iron man athelete) did this about 5 years ago. He fell, broke his back and is now a paraplegic. Don’t mean to be dramatic, just want you to be safe!

Did you install any blocking behind the support brackets? I am concerned that the 1/2 inch plywood won’t support the new roof.

Tom

Yes, there’s blocking inside the wall behind the OSB.

Thanks, that’s helpful.

We are all with you in your ambitious undertakings. How well you think things through! It is fun to see your progress along the way. One thing I think we would all love to see is a picture of you waving at us from that doorway. How about it? It would make our cheering you on even more personal.

I am always surprised at her mad skills level. She is just amazing to me. In case you were wondering what I think of her: Skill Level EXPERT.

Sorry not using the word fabulous today 😀

You don’t need my affirmation but I swear every time I consider a project I’m going to channel YOU! I know I will have success. Just painted a headboard, it turned out great. Catch is I had wanted to leave wall paint alone (daughter painted last year turning 2 bedrooms into her suite), now returning to guest room and studio. My color choice fights a wee bit with her wall paint. Lesson learned, even in the best of light, neutrals (HER taupes) don’t always look neutral with other colors. What looked like pale butter & white in my garage looked darn bright in the guest room. Oh well I did use Fusion paint which I believe I learned of through you. Very Happy with the paint.

I adore how you have details that add so much without being fussy. Impressive work, always.

I love the plan, but doesn’t the siding go on first?

No. The portico goes on first, and the siding butts up to the sides of the framing. In fact, it’s easier to do the whole thing, including the shingles, before the siding goes on since the flashing on the portico roof has to go under the siding. If you put the portico on top of siding, you have gaps between the portico framing and the siding since siding overlaps, making it an unlevel surface. And I have no idea how you’d flash the roof of the portico if you put it on top of the siding. I’ve seen it done that way, and it doesn’t look good at all (in my humble opinion). It looks like an afterthought rather than planned part of the house. You can see that the one in the first picture was either installed before the siding, or they cut away the siding where the portico framing needed to sit directly against the sheathing of the house.

I see separate pieces of wood cut and fit in behind the braces with a seam between the two. My computer can blow things up quite large. I like the idea of bracing against a smooth surface, though.

It might be extra caulk that I’m seeing that looks like a seam. I just checked it from the outside and not the inside, so you are most likely correct.

OSHA? Look at blogs from Costa Rico of workers doing construction and you’ll find your method looks perfectly safe by comparison.

Haha! True! But I don’t think you have to go even that far. When the guys were working on reframing my ceiling, they built a makeshift scaffolding out of scrap lumber. It made me so nervous! I couldn’t believe they were actually standing on top of that thing! 😀

Matt, I so agree with you! Your wife is amazing! I have been fallowing her for the past three years and she is got talent! But FABULOUS she is! Haha!!

I don’t envy you in that heat. No way could I be out there, but then I’m 63 years old too! Doing this work by yourself is amazing! I’m surprised your neighbor didn’t come to assist you. If we were neighbors, my hubs would have been there helping in a heartbeat. Sometimes I think he lives to help the neighbors, but he never asked for help until this year. And THAT is a miracle! Your project is coming along great, but I hope you are hydrating and not pushing too hard!

That’s pretty brilliant…

I got a quote for a portico that was $10,000! It had fiberglass columns instead of the corbels, but I imagine that the construction is similar.

Wow! $10,000, that is crazy! I have fiberglass columns holding up my portico. One less thing to rot. (There is a beautiful historic mansion in our town with beautiful wooden columns that are totally rotted!) So I like fiberglass & vinyl. Even though it doesn’t look as good.

I’m also good with the fiberglass, but not so good with the $10K. I’ll be diligently tuned to Kristi as she finishes this project, hoping to save myself about $9K.

Rebecca -I’m also good with the fiberglass, but not so good with the $10K. I’ll be diligently tuned to Kristi as she finishes this project, hoping to save myself about $9K. What an inspiration she is!

You do have amazing skills, but also a lot of spunk for building a portico right in the midst of professional builders at your house! You are not intimidated by them and I’ll bet they are all super impressed!

Agree. I’d love to be able to do that.

It is going to be wonderful! True Portico story: I have a bat problem, found one in the house the other night, luckily we got it safely out of the house by trapping it in a plastic container (and releasing it into the night unharmed). So we had a “critter control” guy out who pointed out bat crap on our front cement stoop. Right under the portico. Apparently they are literally hanging out during the day in a small gap where the portico meets the front of the house. And crapping in front of our door. So you might want to use some caulk or some mesh when all is said and done.

Kristi is the queen of caulk, but after reading your very batty experience she’ll probably amp up the caulk even more. lol

Awww that was a cute pun.

Simple solution would be to put up a bat house away from your door! They really do eat tons of bugs at night. I intend to try to build one after I’ve done more construction and have scraps to use. Don’t go batty, get batty! LOL!

Love these simplified rafter cuts! I need to re-roof a shed and need to know these things!

A few years ago Home Depot had a sale on mini scaffolding. It was $99 or some such. An extravagance I know. Hemmed and hawed about buying it but I am a little taller than you (5′ 1 1/2″) and a whole lot older and was nervous about my ladder. I love the thing. I have used it so many times and it folds and stores beautifully. Since then I have bought a better ladder and a work platform. The platform is great because you can walk back and forth on it (don’t have to get down and move the ladder) but sometimes it is too short and that is where the scaffolding comes in handy. Have never regretted the purchase. I just love the way your studio is coming along. Great job.

Not to offend, but….

There are reasons for Osha and hiring skilled, union labor. And unfortunately we just witnessed 2 examples. While I love watching you transform your home, there is a reason to do things right.

I’m not offended, but I am amused at the thought of hiring “skilled, union labor” to build a tiny portico that any DIYer could build.

Just because someone has been doing it for 25 yrs does not mean they were trained to do it correctly…and I was referring to the contractor 😉 unfortunately this is what we can thank all our DIY shows on TV for. While they may look fine or even pretty at the end how they were constructed is mind boggling with unsafe/dangerous practices. Let’s all run around a construction site in flip flops shall we 🙂 I give you huge kudos in tackling all you do…but safety should always come first…this was the first time I really felt the need to voice it.

And interestingly, the “skilled” and very experienced framers that worked on my studio and reframed the ceiling created makeshift scaffolding out of scrap lumber (which you can see in the bottom of this picture). It was rickety and scary, and I couldn’t even watch them stand on it as they lifted that massive LVL beam to the ridge of the ceiling. It freaked me out that they were doing that, and they’re pros who do this stuff every single day.

They also made their own scrap wood scaffolding to install the top row of OSB on the gable side of the studio, which you can see here. My brother and I stood there for a few minutes watching with our jaws dropped at that sight.

So that’s how the “pros” get it done here in central Texas. I can guarantee you that my truck bed is many times more stable than their makeshift scaffolding that the “pros” used while working on my house, which you couldn’t pay me money to climb on.

You are a rockstar! Thanks for inspiring us all and sharing your projects with us!

Do you climb that ladder with it leaning against the house like that? Yikes! A friend went down with her ladder using it like that and majorly injured her shins and legs! Please be safe!

Holy shit. You can do anything!

Not sure how your truck bed looks, but hope you place some plywood down to level/true up the surface the ladder is on. The in-laws hired painters to paint a ceiling in the past… this was a 24’+ ceiling in a giant room, the painters were a circus act apparently because 2-3 would hold the ladder vertical while their co-worker was at the top.

That looks pretty good, so far. Be careful with your ladder tricks. I know a guy who took a nasty tumble off his ladder set up in the back of his pickup. He spent a LOT of weeks in traction, therapy and off work.

I’m not condoning the ladder in the truck idea. But honestly anything can kill you. A friend of mine had a family member who went up a regular little old step ladder and slipped and fell. Hit his head “just right” and spent the next three months of his life in the hospital before passing away. It was just one of those freak things. Not because he was using a ladder unsafely just because of plain misfortune. If only he hadn’t gone up that ladder, but we all do! I fell off my own little step ladder a few years ago. Nothing dramatic I thought, I missed the last step and went straight to the floor. Landed poorly and broke my big toe. Spent the next six weeks forcibly taking it easy…

Anyway, try not to do anything too scary!

Mark

Oh wow! It amazes me what you take on…. A woman of many talents! Pinning in case we ever put a portico on our house:) Construction is so exciting.

This has been the most helpful information on this topic I have found. Thank you! You saved us!

Thank you so much for posting! We used your tutorial to build ours while re-siding our house and we absolutely love it. I’d be happy to share photos!

I’d love to see pictures! You can send to: [email protected]

Hi, love this portico, exactly what I’ve been looking for, if I wanted it to come out more than 24″ maybe 36″ do you think I would need column’s? We get snow, so worried about weight, but would rather not.

I am not in any way qualified to give you input on that. I’d think it would depend on whether or not you can find supports that are that large. But whether or not it’s a wise thing to build it out that far is something that someone way more qualified than I would have to answer for you.

Well done! Your pictures and explanations have taken out the mystery of how to do those cutouts, thanks!

Thank you SO MUCH for sharing this post!!! You made this project so do-able! This one definitely goes on my list!!!